MV Accessories Distributor Case Study: Thorne & Derrick International

Thorne & Derrick International, based in Bristol UK, are Specialist Distributors of Medium Voltage Jointing, Earthing, Substation and Electrical Equipment up to 66kV.

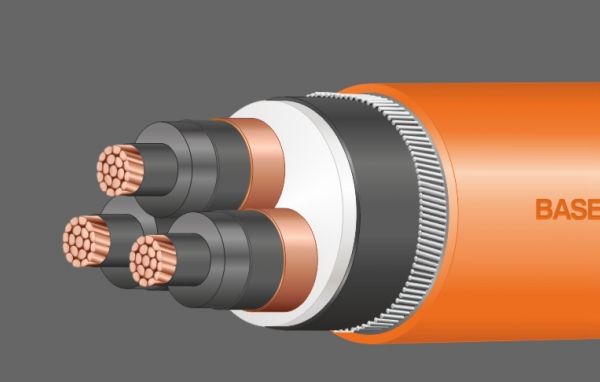

The company supplies Joints and Terminations to connect MV Power Cables (11kV-33kV) in the onshore and offshore wind, solar, rail, oil and gas, data centre, battery storage and utilities sectors.

Thorne & Derrick are committed to BASEC and providing BASEC Approved Cables where such product approvals exist from their extensive stocks and supply-chain. The distributor prides itself on having considerable MV technical expertise and providing world-class customer service and support.

Worldwide supply solutions

Established in 1985, Thorne & Derricks’ product portfolio covers Cable Installation, Jointing, Substation and Electrical Equipment, including Terminations and Connectors up to 66kV from their wide-ranging stock. Thorne & Derrick distribute cables produced by manufacturers such as Prysmian, as well as MV Cable Accessories & Preparation Tools from manufacturers such as 3M Cold Shrink, Nexans Euromold, Pfisterer CONNEX and Alroc.

The UK distributor claims their multi-million-pound stock holding facilities provide both UK and worldwide supply solutions via their Export Sales Department.

Increased demand for power and combating non-compliance

The increased demand for power is a global trend and according to a recent report by McKinsey the demand for European power alone will increase by 40% until 2050: from 3,500 TWh in 2020 to 4,900 TWh.

This will place considerable pressure on existing and new power systems to perform, regardless of the industry sector.

In addition, the rise in demand for digitalisation, coupled to major developments in providing Green Energy have further heightened the industry need for MV power, to which cables and cable accessories are central to the system in transmitting and distributing electricity efficiently and safely.

Subsequently, in line with this surge in demand, it is vital that the cables used in power infrastructures have been tested and verified accordingly, to provide assurance that they are fit for purpose.Non-compliant cables are unable to demonstrate that they meet required levels of quality, which can result in major failures, causing costly damage and putting consumers safety at risk.

Thorne & Derrick, together with BASEC have a shared passion to enhance electrical safety and provide peace of mind to end users. This is driven through the education and encouragement of industry stakeholders, such as electrical engineers, to specify and purchase third-party tested and certified MV cables and cable accessories, whatever the industry. The shared objective supports verified electrical systems that are safe and perform efficiently, providing assurance throughout the supply chain.

The value of BASEC product approval

The importance of good quality cable that is both compliant and safe cannot be understated. The BASEC mark is trusted around the world as a symbol of premium quality and achieving certification is not easy. To gain BASEC approval cables are subject to stringent ongoing testing and audits twice a year combined with an unannounced visit to the manufacturer to ensure continued cable conformity.

Chris Dodds, Sales and Marketing Manager at Thorne and Derrick International comments “At Thorne and Derrick we understand and cannot stress highly enough the criticality of specifying and supplying MV cables that have been third-party tested by Approval Bodies such as BASEC as well as independently approved MV accessories in line with British and international standards to ensure the safety, reliability and longevity of MV power systems.’

Learn more about Medium Voltage cable testing and the investment BASEC has made to support this market and provide third-party assurance of quality here.

Contact the team at Thorne & Derrick International to discuss their Cable Accessory and Equipment offering.