A technical view of the importance of Medium Voltage (MV) cable Testing

Technical insight on critical testing and the difference between MV and LV cables, and additional testing needed for MV and the role of an independent third party and accredited body.

For medium voltage cables, testing is even more critical than low voltage counterparts due to the design's complexity and ensuring the highest level of safety and proper operations with the higher voltages. Testing is always a necessary action to verify the quality.

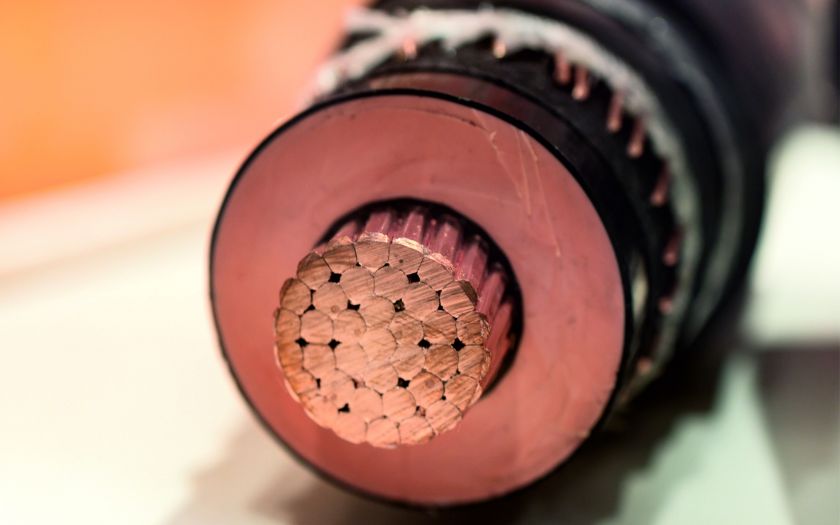

The insulation layer withstands higher voltage levels experienced by medium voltage cables - the insulation layer's purpose is to provide sufficient resistance to ensure that the current maintains its path alongside the conductor at the higher system voltage ratings. Therefore, an appropriate insulation layer should be applied; the insulation layer in the cable differs in the material used, the processing, and even the testing done.

The insulation layer for medium voltage cables consists of three layers: conductor screen, insulation, and insulation screen. The higher voltage levels applied to these cables need a progressive transition from the conducting medium to the insulation. For example, a conductor screen is used to guarantee a uniform electric field in the interface between the insulation and the conductor and prevent any electric field concentration, as this concentration will create high-stress points at the conductor/insulation interface. Conductor and insulation screens are semiconductive, so they are neither a conductor nor an insulator.

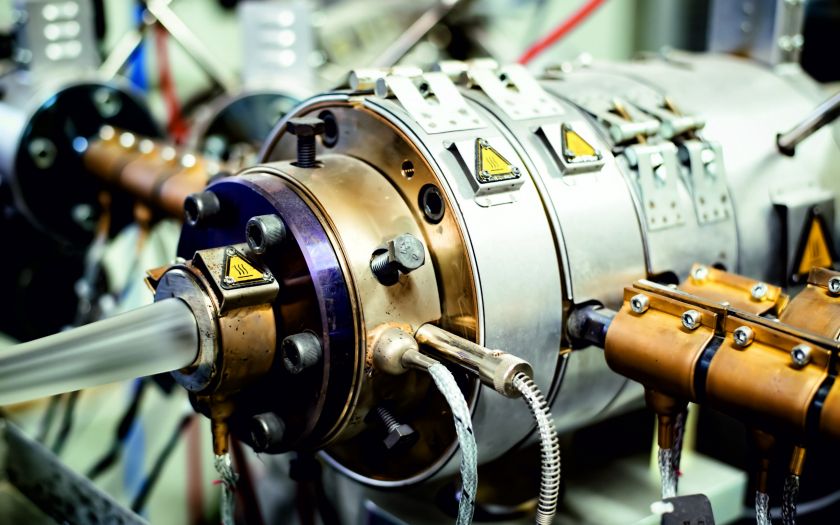

Furthermore, the processing of the three layers for MV insulation should be done simultaneously by a unique head/machine, and the extruder itself is entirely different from the regular horizontal extrusion lines used for low voltage cables. The Medium Voltage machine is called a CCV line (Catenary Continuous Vulcanizing) which includes triple heads to simultaneously extrude the three layers (conductor screen, insulation, and insulation screen).

This complexity in the construction and process of medium voltage cable is reflected in the testing, making testing of medium voltage cables more complex than regular low voltage cables. Not only due to the higher voltages that are applied but additional tests that should be done to medium voltage cables such as a Partial Discharge (PD) test, Tan Delta measurements, Heating Cycle test, Impulse Voltage test, Adherence of Screens at Short Circuit Temperature test - these tests are not required to be performed on LV cable.

Partial Discharge is a measurable indicator of developing insulation defects in power cables due to internal weak points in the insulation of medium voltage cables, such as voids, cracks, or contaminant particles. In medium voltage cable standards, the maximum detected level of partial discharge within the insulation of MV cable during the type testing is 5 pC or greater, to be considered successful and pass the test. Accordingly, the partial discharge test is vital to check the quality of insulation of medium voltage cables.

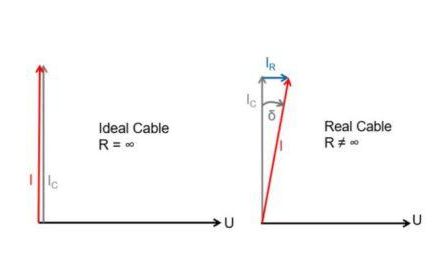

Tan Delta Measurement, Tan delta (δ), is known as Loss Angle or Dissipation Factor - this test is used to determine the quality of the cable insulation. The measured value should be low and not exceed the specified values in the standards at the specified voltage or temperature. This test can be repeated on cables to assess life expectancy and plan or predict maintenance or replacement cycles.

The Heating Cycle test is a pivotal test to evaluate how the complete cable withstands the thermal stress during the operating time of the cable to simulate the actual life scenarios in which the cable will be subjected to heating (when the cable is in service) and cooling (when the load is disconnected for any reason) during the cable lifetime. This is done by induction heating - the conductor is heated to higher temperatures than the rated/designated temperature, which generally is 90 oC; the cable should withstand 20 cycles (each cycle includes heating and natural cooling), and the test is evaluated, the tested sample should be subjected to another partial discharge test.

Adherence of Screens at Short Circuit Temperature test is required within some standards, as the cable may be subjected to short circuit conditions in which the temperature can reach 250 oC; the cable should withstand these conditions even if it is for a few seconds. This test will evaluate that following application of a short circuit current for 3 seconds, when a subsequent partial discharge test is carried out, the discharge magnitude is compliant to the requirement of the standard, and that no deterioration of performance of the insulation system has occurred following the exposure to short circuit temperature.

The role of an independent third party and accredited body, certification and comprehensive testing organisations such as BASEC is to ensure that the required quality level is maintained and the testing regime is in place to complement the standard, and all the critical parameters have been tested.

It is obvious that all the highlighted tests are critical, and the cable performance is tested with an independent ongoing surveillance scheme - that continuously checks the cables' conformity to ensure the quality has not dropped from the first set of initial type testing. Not only at one point in time, like a single type test report commonly used. All these critical parameters should be closely observed and regularly tested to ensure compliance and the quality level are maintained. In addition, the same materials should be used as the first tested sample, which is a standard requirement to validate the performed type test, by a third party like BASEC, through regular factory audits, including supply chain and production records, to ensure that the approved materials are used. Likewise, BASEC carries out material fingerprinting using Thermogravimetric Analysis (TGA) and Fourier Transform Infrared (FTIR) Analysis, which is the only way to confirm the standard requirements of the materials, ensuring that the cables are tested and approved. Besides, relying on a manufacturer's declaration of using the same material will keep the quality level of the cables at risk, affecting the entire project's safety, quality and performance.

BASEC routinely selects more samples than other certified bodies - to ensure that all cables are regularly re-tested. During a BASEC audit, samples are selected independently and sent to the BASEC laboratory for testing. This ongoing testing highlights deviations from the relevant standards and gives the manufacturer regular opportunities to confirm the conformity of their cables. Once a manufacturer receives product approval for a cable, they can mark it with the BASEC Quality Mark. When placed on the market, this gives all stakeholders (utilities, consultants, contractors, and so on) confidence in the ongoing quality and conformity of the used approved cables.

Download your free guide to MV distribution cable standards and power distribution network requirements below.