Case Studies

BASEC is a global leader in cable testing and certification services for power, energy, data/signal cables and ancillary products, alongside quality management systems. Operating independently for over 50 years, the BASEC mark is trusted for quality, safety and impartiality.

BASEC's teams of highly skilled engineers, technicians and auditors possess extensive in-depth commercial, industrial and technical experience. As a result, BASEC has a reputation for professional and rigorous assessment processes which ultimately lead to the issuing of our highly respected product certifications and test reports.

Read our case studies and see why cable manufacturers choose BASEC as their preferred testing and certification partner.

Atom Kablo

Atom Kablo chooses BASEC for Product Certification and Marking for 15 years

Atom Kablo is one of the leading electric cable manufacturers and exporters in Turkey, employing 200 staff across their manufacturing plant in Denizli and their Istanbul Head Office. Established 25 years ago the company operates predominately in the LV cable market in both Turkey and the UK.

Challenge

Exporting to the UK market

Fifteen years ago, Atom Kablo made the decision to begin exporting to the UK market. However, they realised that to achieve this they would need to demonstrate their reputation for quality, safety and traceability specifically to this market.

They needed to achieve ISO 9001 as well as gain product certification of their cables with a reputable and respected Accredited Body.

Outcome

Atom Kablo chose BASEC’s Product Certification Scheme

Choosing BASEC’s Product Certification Scheme gave Atom Kablo ISO 9001 accreditation and enabled them to put the BASEC mark on their cable, giving their new export customers confidence in their cables.

Prior to the initial audit, BASEC was able to give training and guidance on how to approach the specific requirements of the scheme, ensuring it was implemented as quickly and efficiently as possible.

Once they achieved the BASEC mark, the lucrative UK market opened up to Atom Kablo which has resulted in a significant increase in sales.

Services provided

“BASEC auditors are cable specialists, something many accredited bodies can’t offer, so they really understand our business”

- ISO 9001 accreditation

- BASEC Product Certification Scheme (PCR)

Dubai Mall

BASEC approved cable powers world’s largest mall

The Dubai Mall is the world’s largest mall. In 2019 the Zabeel expansion increased its footprint by over 40%. The mall welcomes over 80 million visitors each year and is visited by approximately 98 per cent of all visitors to the city, as indicated in the Dubai Department of Tourism’s annual statistics. The Zabeel expansion added another 3-storey mall comprising of further retail, food, beverage and entertainment facilities to the existing structure, as well as a 20-metre long, 44-metre wide, retail bridge that connects the existing mall to the Zabeel expansion. For a construction project of this size, a variety of cable products must be specified and must consider public safety.

National Cables Industry (NCI) is a leading cable manufacturer that is dedicated to producing cable products to recognised industry standards. With a track record for producing cable products to meet high levels of quality and safety, NCI achieved BASEC approval for a range of cable products, as required within the build specification of the expansion. In this project, NCI manufactured fire-resistant low smoke and zero halogen cable products for use in the supply of power to shops, restaurants and entertainment venues to ensure, for example, that lighting included within the mall and retail bridge could be reliably connected.

Challenge

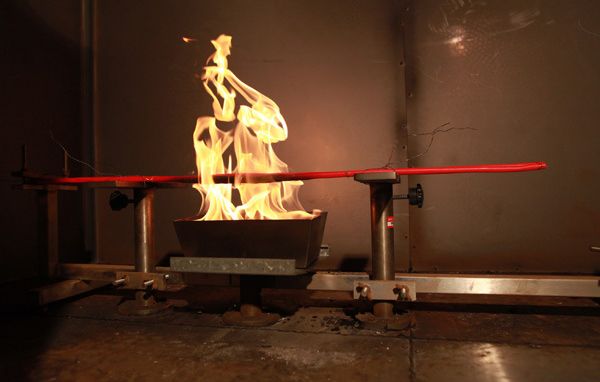

For such a popular destination, ensuring the safety of the public is a high priority. As cables are installed in every part of the Zabeel expansion of the mall, measures must be taken to ensure that any potential for fire risk is minimised. It is for this exact reason that the low smoke zero halogen cable products have been specified, in order to mitigate any additional risks posed to the public in the event of a fire. NCI’s cable products were certified to BS EN 50525-3-41 to verify cable quality, a British and European standard, which applies to flexible cables used in power installations that are often placed within domestic settings and industrial equipment.

The standard requires cable products to demonstrate low levels of halogen presence within the insulation’s construction. Halogens release larger quantities of smoke; testing is therefore conducted to ensure the release of smoke is minimal and within the standard’s requirements. This ensures that if the cable was to come in to contact with fire and burn, the emissions of smoke given off will be within a safe limit. To verify performance and measure the release of these halogen gases, an acid gas determination test is conducted. During the test, the gases emitted are collected and chemically analysed to assess the halogen contents. The standard also involves and requires further electrical, mechanical, material, chemical and fire & smoke tests to verify the complete quality and safety of the cable product obtaining the product certification.

Outcome

Partnering with BASEC ensures cable products have been independently and rigorously tested. Product certification is provided in line with the criteria of the industry standards, required for application. Recognising the importance of independent testing, NCI insists on having their products benchmarked against and in compliance with the industry standards applicable to the quality and safety needs of the end project use.

In cases where a customer simply requests for cable products to tested for one performance criteria, for example to be safe in the event of a fire, consideration for other performance characteristics such as material or construction durability may not have been taken. If repairs are required after installation a lack of reliability and durability of a product, due to an incomplete performance assessment, could impact on operations further down the line. Having not fully understood how a cable could react in extreme conditions there could be a number of effects that may result in operational complications, consequently resulting in the Mall, or similar public venues, not being able to trade or partial closures as well as financial losses.

Services provided

For the Dubai Mall, the use of BASEC approved cable products provides peace of mind that the cable products installed will not only successfully minimise risks to public safety, but will also provide excellent value in the form of durability and years of reliable service.

BASEC is a leading provider of cable product certification, which is amongst the most rigorous in the industry. The certification product approval includes comprehensive testing for electrical, mechanical, material, chemical, and, fire and smoke performance characteristics. Providing cable testing to ensure products are compliant with the relevant local, international, British or European standards.

BASEC is recognised worldwide for its’ commitment to ensuring cable products meet industry standards for quality and safety, in every application, regardless of age or sector.

Be part of the journey.

Lusail Plaza, Qatar

BASEC approved cable keeps Qatar’s smart city moving

The city of Lusail has been heralded as Qatar’s city of the future. This city’s construction is planned to sit on the coast of Qatar and is located approximately 23km north of the centre of Doha. Lusail is designed to be a true ‘smart city’, comprising of both wired and wireless communication networks that residents and visitors alike can access from any place and at any time. The city extends across an area of 38 square kilometres and includes 4 exclusive islands and 19 multi-purpose residential, commercial and entertainment districts. While the city will initially have the capacity to home approximately 200,000 residents, the total estimated population of Lusail when the project is completed will rise to over 450,000 people. In order to keep residents moving around the city, a Light Rail Transit (LRT) project is under construction, which has been designed to include a 30.5km track and 37 stations, with 4 of the lines covering 10km of underground tunnels each. With quality and safety a key requirement for this project, it should come as no surprise that BASEC approved cable has been specified for installation in these stations.

Challenge

The success of the city of Lusail depends on ‘smart’ services being reliable and available. In the same way that the integrated networks deliver services to the residents of the city, the LRT has the potential to become a preferred method of transport, helping residents to travel to their homes and places of business. With global warming and the move to find sustainable sources of power a major concern for the region, a smart city that also takes advantage of wind and solar power technologies can bring great potential for Qatar. Take for example the bid to host the 2022 FIFA World Cup, for the first time ever football’s biggest tournament will be held in Qatar, Middle East. A purpose built solar-powered, carbon neutral stadium gives the region an opportunity to showcase the drive with which it is supporting technologies that will enable a sustainably-powered future. During the tournament and on a day-to-day basis, the LRT will keep the city moving, and systems must be specified and designed to ensure there are minimal disruptions to public transit, so that those travelling are able to arrive at their intended destinations safely. With reliability fundamental to the ongoing operation of the transport network, in such a large city, any failures specifically related to the cable product functions could cause knock-on effects where, not only the carriages cannot operate, but information displays, access gates, elevators and escalators could also malfunction. Even more critically, faulty cable products could prevent rail signals from transmitting, which could potentially lead to a collision between multiple vehicles and result in injury to passengers or, worse, fatalities.

Outcome

The cable products specified for installation into Lusail’s LRT network have been tested to BS 6724 to ensure they meet the highest standards for quality and safety. This standard is designed to assess the suitability of medium voltage armoured cables for fixed installations and is also applicable to the control cables used for applications such as signal transmission, process automation, measurement, control and regulation. Ensuring there is sufficient armour included in the cable’s design is extremely important for this type of cable product; and therefore the standard requires chemical testing is conducted to assess the weight of the zinc coating applied to armour wires. Zinc is applied to the steel armour wiring to safeguard against corrosion, as it provides long lasting protection. Corrosion can be the cause of many electrical faults, so testing to confirm the quantity of zinc applied is in line with the standard’s requirements is key. BS 6724 is also designed to test a cable product’s production of acidic gases when affected by fire. These tests are undertaken to measure how much, if any, gas or other emissions are released from a cable. Cable products constructed from materials with low smoke or gas properties are an essential criteria for cable installations in enclosed public spaces, especially in a metro station scenario.

Partnering with BASEC to conduct independent testing provides a mark of reassurance for those manufacturing, specifying and installing cable, as a symbol to confirm that it will function as intended to in the conditions it has been specified for. The mark of independently approved quality and safety is only awarded when cable products have been rigorously tested to the highest levels required to meet industry recognised standards. BASEC’s cable product certification is designed to include testing for electrical, mechanical, material, chemical and fire & smoke performance, in line with British, European, International and local standards, as well as any sector or industry-specific standards. While manufacturers have their own quality assurance processes, independent testing ensures cable products are assessed to the same standards as other products in the market, to provide an objective verification of their quality and suitability for the application.

Services provided

Approval of the cable products specified for Lusail’s LRT project in line with the BS 6724 standard, by BASEC, offers peace of mind to those specifying and installing the cable. Unbeknown to them, ultimately the city’s visitors and residents who make use of the rail services will also benefit from quality and safe cable products, used and enclosed within the systems which will operate the gates, displays and train carriages. The project owners can be confident in the knowledge that the cable products specified have been tested to and comply with all of the relevant regulations required for their application.

The BASEC name is synonymous with quality and safety and our independent cable certification and testing is trusted and respected around the world. Our comprehensive product testing approvals, stockists and control cable certification schemes provide purchasers, contractors and end users with the peace of mind that the cable they install is compliant, safe, fit for purpose and will provide years of reliable service.

BASEC is a recognised sign of assurance, symbolic of independent cable testing and approval, supporting the worldwide cable industry.

Be part of the journey.

Western Power Distribution, United Kingdom

Tratos supplies BASEC approved Medium Voltage Cables into large electricity distribution network

Western Power Distribution (WPD) operates one of the largest electricity distribution networks in the United Kingdom, supplying power to more than 7.9 million customers, over a 55,000 square kilometres service area. In addition to connecting new homes and businesses to their electricity network, WPD is responsible for the operations and maintenance of power lines and for returning excess electricity to the National Grid. As the sole electricity distribution network operator for South Wales, the Midlands and the South West of England, the installation of quality cable is critical to the success of the business.

Challenge

Underground transmission cables perform the essential function of carrying power between substations and buildings. As these cable products are buried underground, quality materials are essential to ensuring that these products operate effectively in the underground conditions, and will not require anything more than the minimal maintenance that can be delivered once in-situ.

In order to ensure the efficient and consistent supply of power to these areas WPD contracted Tratos to supply Medium Voltage (MV) cables into the network and to maintain their stock. Tratos is an innovative cable manufacturer which produces cables to the high standards required by industry. In this case, Tratos supplied 11kV and 33kV MV cables to be used in a wide range of applications, including underground power lines, power distribution, and mobile substation equipment.

Outcome

BASEC certification is used throughout the worldwide cable industry to demonstrate that the cable products manufactured meet the highest quality and safety criteria in line with recognised standards. Tratos has achieved BASEC approval, on key products, to evidence their levels of compliance, quality and suitability for use in a range of specific applications, for examples in their primary business offering of power supply, as well as for a number of industry standards including CPR and management systems approvals. The cable products supplied by Tratos into WPD were rigorously tested by BASEC and approved to BS 7870-4.10, a standard specific to power distribution, applicable to a wide range of cable applications between 6.35 and 33kV. One of the key tests the standard specifies is the Shrinkage test, which is designed to determine the amount of shrinkage that may occur when insulation is exposed to high operating temperatures. The test is extremely important for underground transmission cables. If the amount of shrinkage is excessive this could lead to conductors becoming exposed during their normal use. As the first cable manufacturer, in Europe, to achieve BASEC approval to meet this standard, Tratos reinforces their commitment to meeting high levels of quality and safety, and to all relevant regulations. In turn, ensuring that the end user of their product can be confident that the product meets the required standards and is fit for purpose.

Any successful cable manufacturer conducts in-house testing, but most importantly also undertakes independent testing to ensure that their cable products meet the standards required before releasing them into the market. Pressures to meet commercial targets and achieve greater production efficiencies can mean that sometimes, in-house testing can be less stringent than a dedicated independent testing house. By undertaking product testing through an independent certification body, like BASEC, a manufacturer can benefit by enhancing their reputation by leveraging the BASEC brand as a value-add. Recognised brand marks, accreditations and certifications are used in end user markets, such as rail, utilities and power, oil and gas and many others, in order to provide the end-to-end supply chain with assurance that cable products are compliant and will also perform as they say they will. Only when cable products have been rigorously tested to the highest industry recognised standards is the BASEC mark of independently approved quality and safety awarded for use.

Services provided

By partnering with BASEC, Tratos demonstrates their dedication to ensuring that their customers and end users have access to compliant cable products that meet the highest levels of quality and safety, for use in some of the world’s toughest and highly regulated environments.

The BASEC name is synonymous with quality and safety. BASEC is trusted and recognised as the independent mark of cable testing and certification for the worldwide cable industry.

Be part of the journey.