Chemical Tests

BASEC conducts a number of chemical related tests on cable materials. These tests are specified in cable and material standards and are called up for a variety of cable types.

Navigate Chemical Tests

Ozone testing

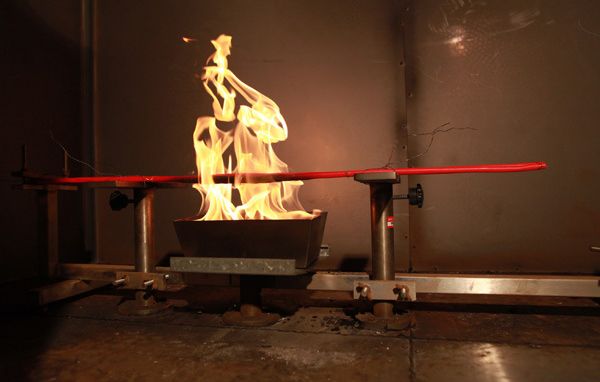

Resistance to ozone testing is conducted in-house and is critical to a cable’s performance. Assessment of the deterioration caused by ozone exposure is designed to provide an indication as to how the component will perform over time. Ozone is a naturally occurring substance which erodes compound mixes containing polymers, rubbers, silicones or elastomers.

Cases of unsatisfactory, unsafe or non-compliant materials will often result in cracks or surface breaks, which in operation can lead to serious product failures or problems. Testing enables product designers to revise compound mixes to reduce the impacts of ozone exposure.

Example Cables

Applied to cables such as BS 8592 and the following:

Test Methods & Equipment

ASTM, BS or ISO test methods can be used.

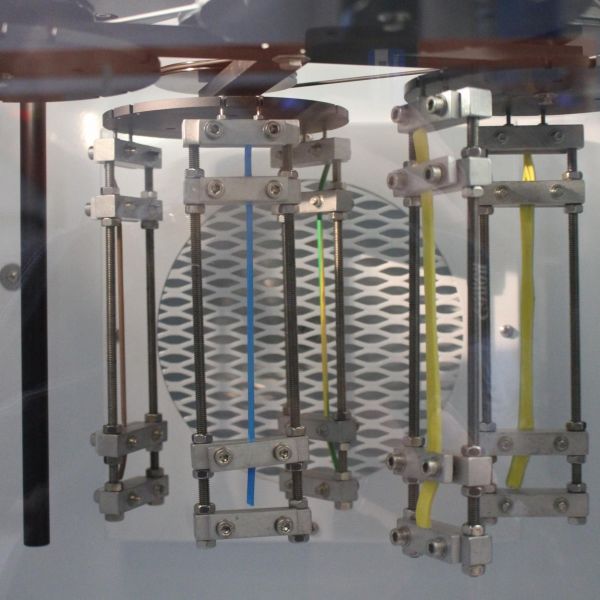

During the testing, samples are placed within the ozone chamber, where concentrated volumes of ozone are released in accordance with the required test standard. The test chamber is used to simulate accelerated assessments of the effects of ozone.

Corrosive and Acid Gas / pH and Conductivity / Halogens

Tests for corrosive and acid gas, pH and conductivity, and for the presence of halogens are specified in many standards for low smoke, halogen free (LSHF) and related cables.

Example Cables

Each cable standard specifies different combination of these tests.

Test Methods & Equipment

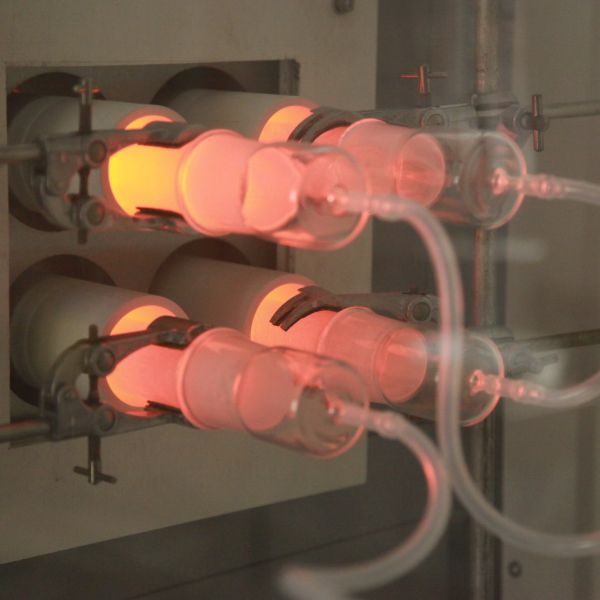

Test methods are specified in BS EN (IEC) 60754-1, BS EN (IEC) 60754-2, BS EN 50525-1.

The main test equipment is a high temperature tube furnace, in which small samples of insulation or sheathing material are pyrolysed at around 850C. Gases emitted are collected in wash bottles, and the chemical content is then analysed by a number of techniques, including titration, pH / conductivity electrodes, and ion chromatography. A small scale test for halogen content involves burning the material in the presence of sodium metal.

Tin Coating of Conductor

Certain cable types where a copper conductor such as a CPC or drain wire might be in contact with an aluminium tape or foil specify that the copper conductors must be tin coated, with no pinholes. Tests are undertaken to check the thickness of tin coating and for the presence or absence of defects.

Test Methods & Equipment

The conductor is carefully removed from the final cable, and immersed in a chemical reagent which seeks out visible copper. In one variant of the test, the copper is dissolved and then analysed. In a more recent variant, the presence of visible copper results in black spots appearing on the conductor, which are examined by the eye.

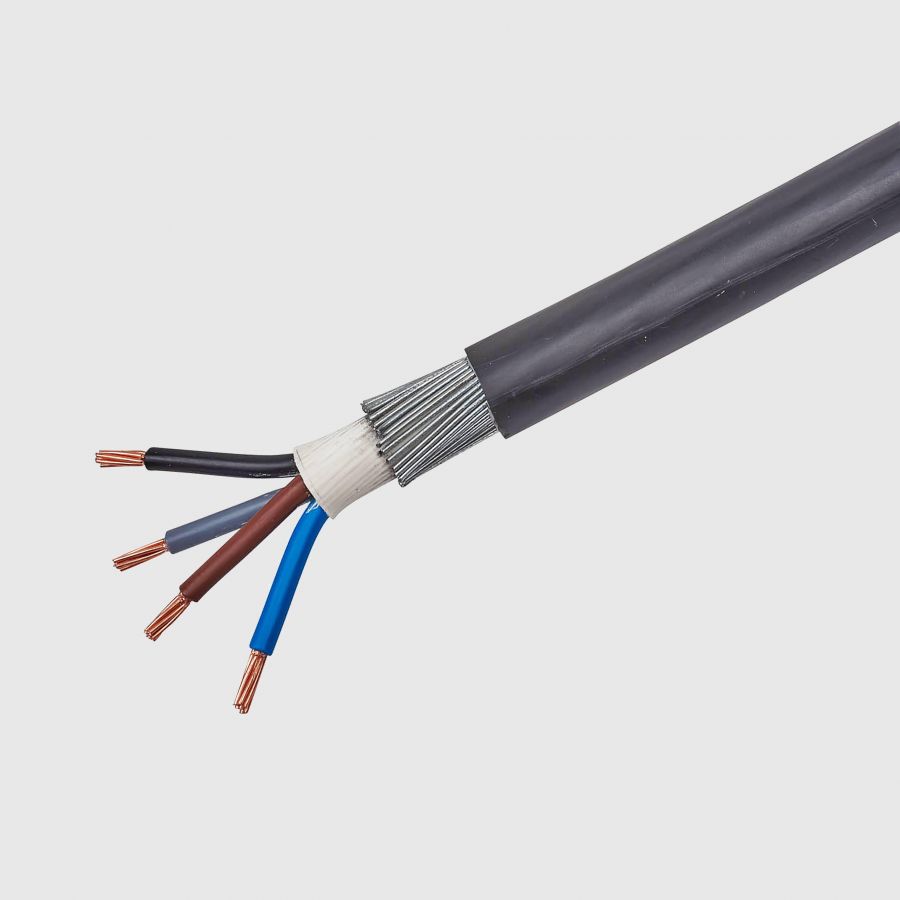

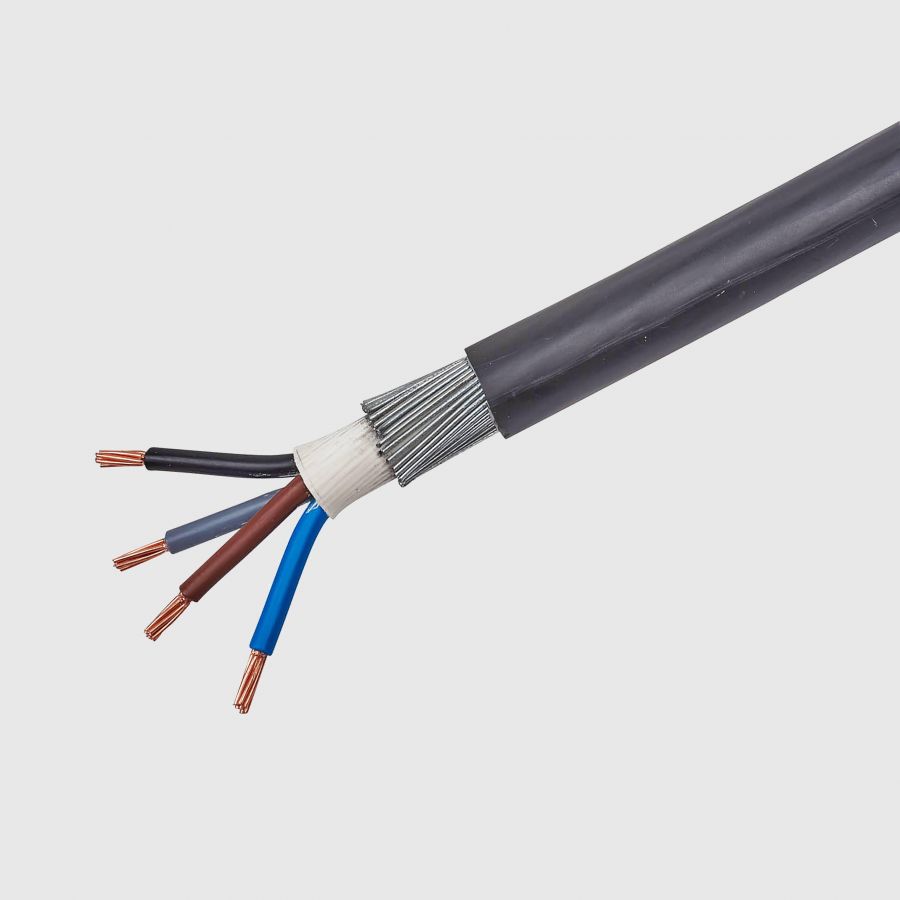

Zinc Coating of Armour Wires

Steel wires used for mechanical protection in armoured cables must retain their integrity over many years of use. In addition, where these wires are used as a circuit protective conductor, they must not corrode away over time, as this would reduce the conductivity of the armour. For this reason, cable standards specify that the wires should be zinc galvanised, with minimum weights of zinc applied.

Example Cables

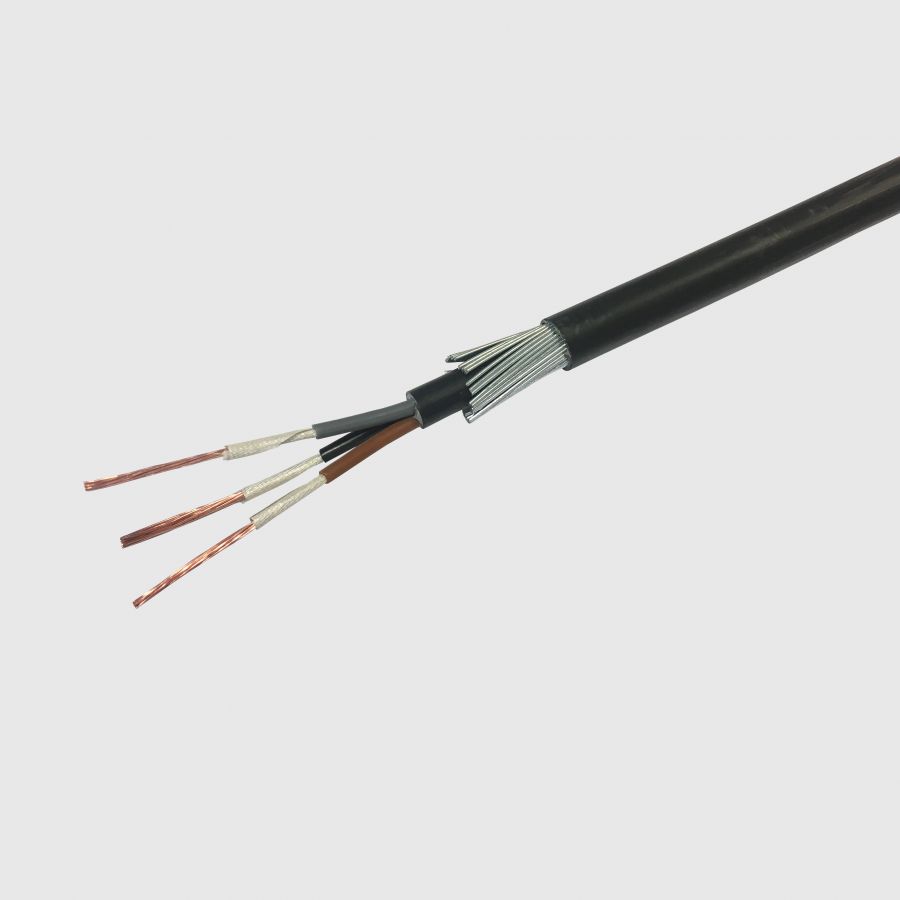

These tests are commonly applied to British armoured cable types, such as:

BS 7846

Fire resisting armoured power cables with low smoke halogen free (LSHF) sheathing, and enhanced circuit integrity properties. Commonly known as fire resistant SWA, fire alarm / emergency lighting cable / soft skin fire alarm cable.

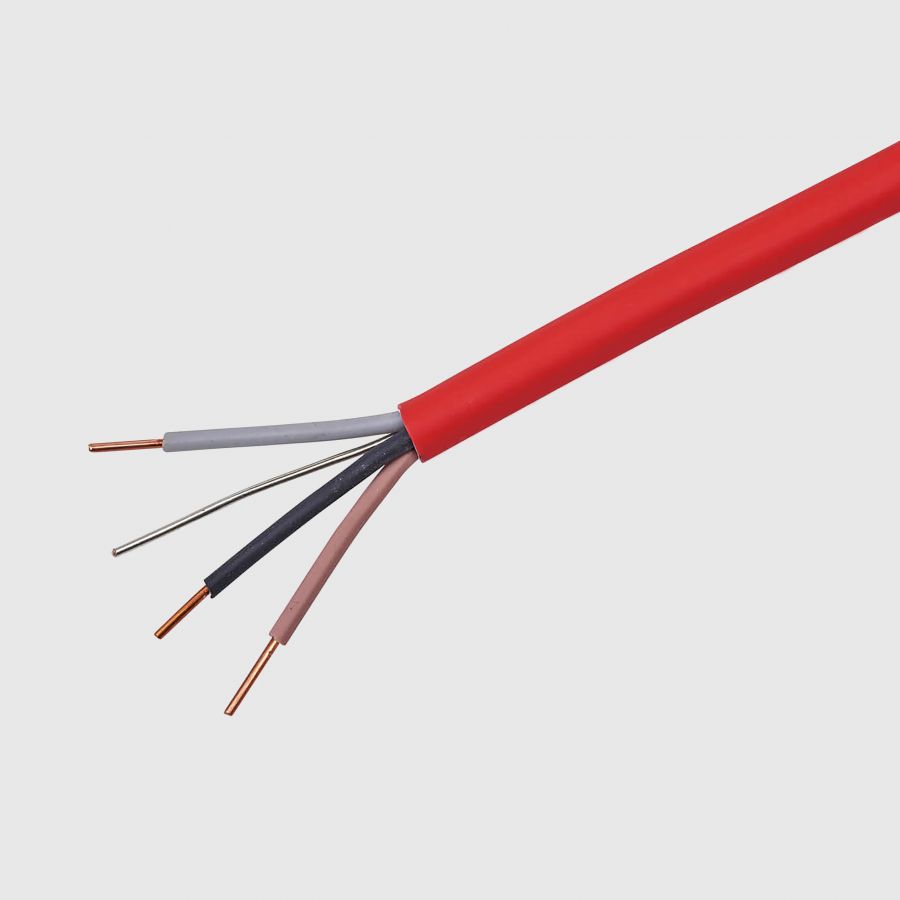

BS EN 50525 Series

Harmonised European standards for flexible cables. HAR scheme approval for these and other cables is also available.

BS 7629-1

British Standard type of “soft skin” fire resistant screened cables commonly used with fire alarms and emergency lighting. Commonly known as fire alarm / emergency lighting cable / soft skin fire alarm cable.

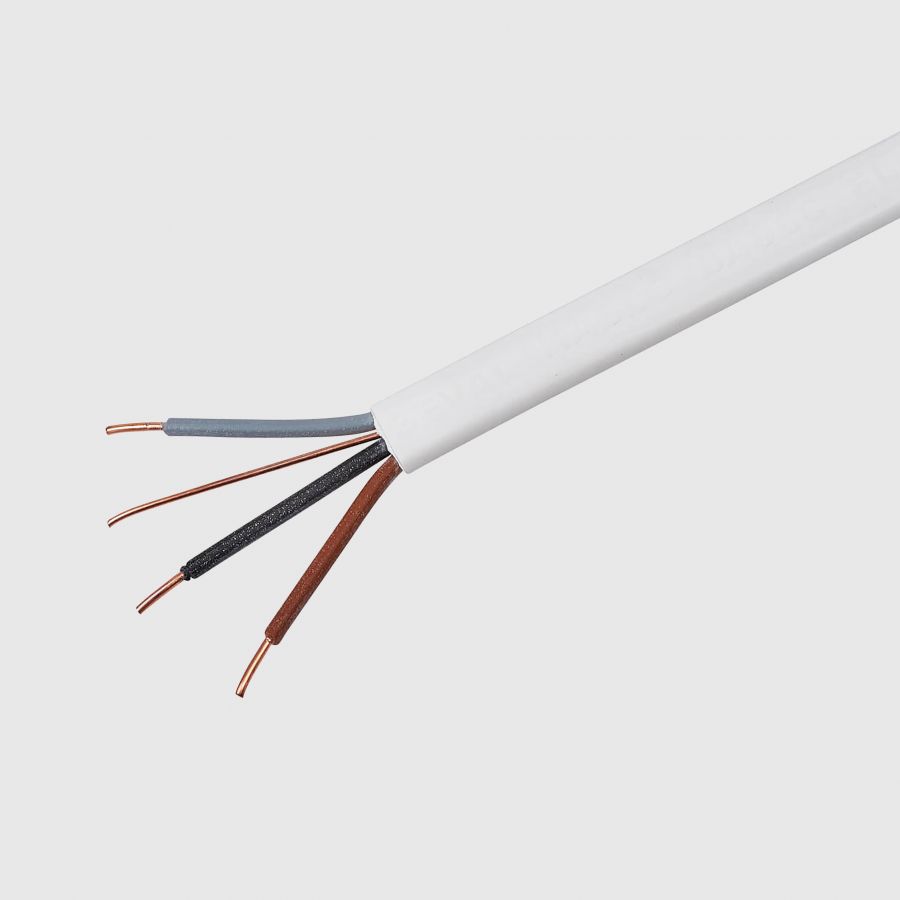

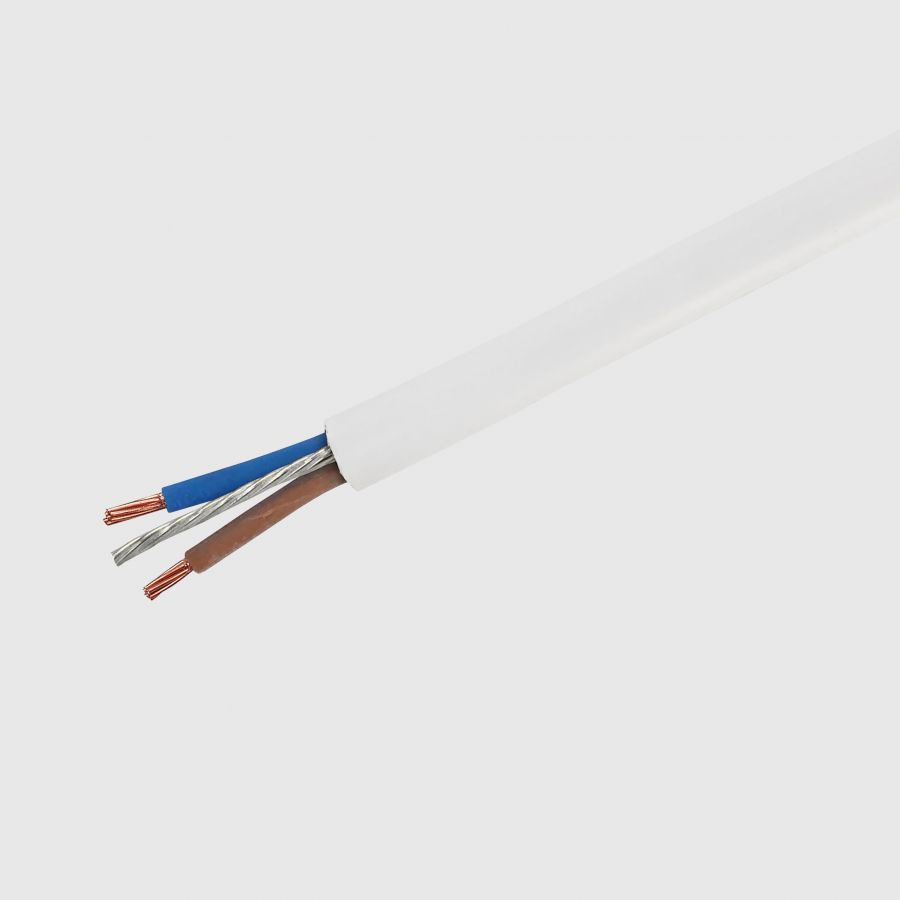

BS 7211

Low smoke halogen free (LSHF) versions of many of the types of wire and cable found in BS 6004. Commonly known as low smoke twin and earth, 6242B, 6243B.

BS 6724

Armoured power cables with low smoke halogen free (LSHF) sheathing. Commonly known as low smoke sheathed armoured, SWA, AWA.

BS 8573

Non-armoured power cables with low smoke halogen free (LSHF) sheathing. Commonly known as low smoke sheathed unarmoured power.

BS 7835

Armoured medium voltage cables with low smoke halogen free (LSHF) sheathing, for rated voltages up to 33 kV. Commonly known as low smoke sheathed MV.

BS 8436

Multi-core screened cables with low smoke halogen free (LSHF) sheathing for use in walls, partitions and building voids. Commonly known as nail proof.

BS 5467

Armoured power cables with PVC sheathing. Commonly known as PVC sheathed armoured, SWA, AWA.

BS 6622

Armoured medium voltage cables with PVC sheathing, for rated voltages up to 33 kV. Commonly known as PVC sheathed MV.