Case Study: The role of cables in Particle Physics at CERN

As a European organisation operating highly innovative particle physics research projects, CERN uses the world’s largest and most complex scientific instruments. Founded in 1954 and based in Geneva, on the France-Switzerland border, there are approximately 2,500 staff who are responsible for designing, constructing, and operating the research complex.

CERN is described as a ‘unique collaboration of countries, universities, and scientists committed to creating and sharing knowledge, to provide insights and scientific advancements and help the society around the world.’ The organisations’ extensive expertise spans various industries, including aerospace, healthcare, quantum, digital, and environment.

Cables supporting Particle Physics infrastructure

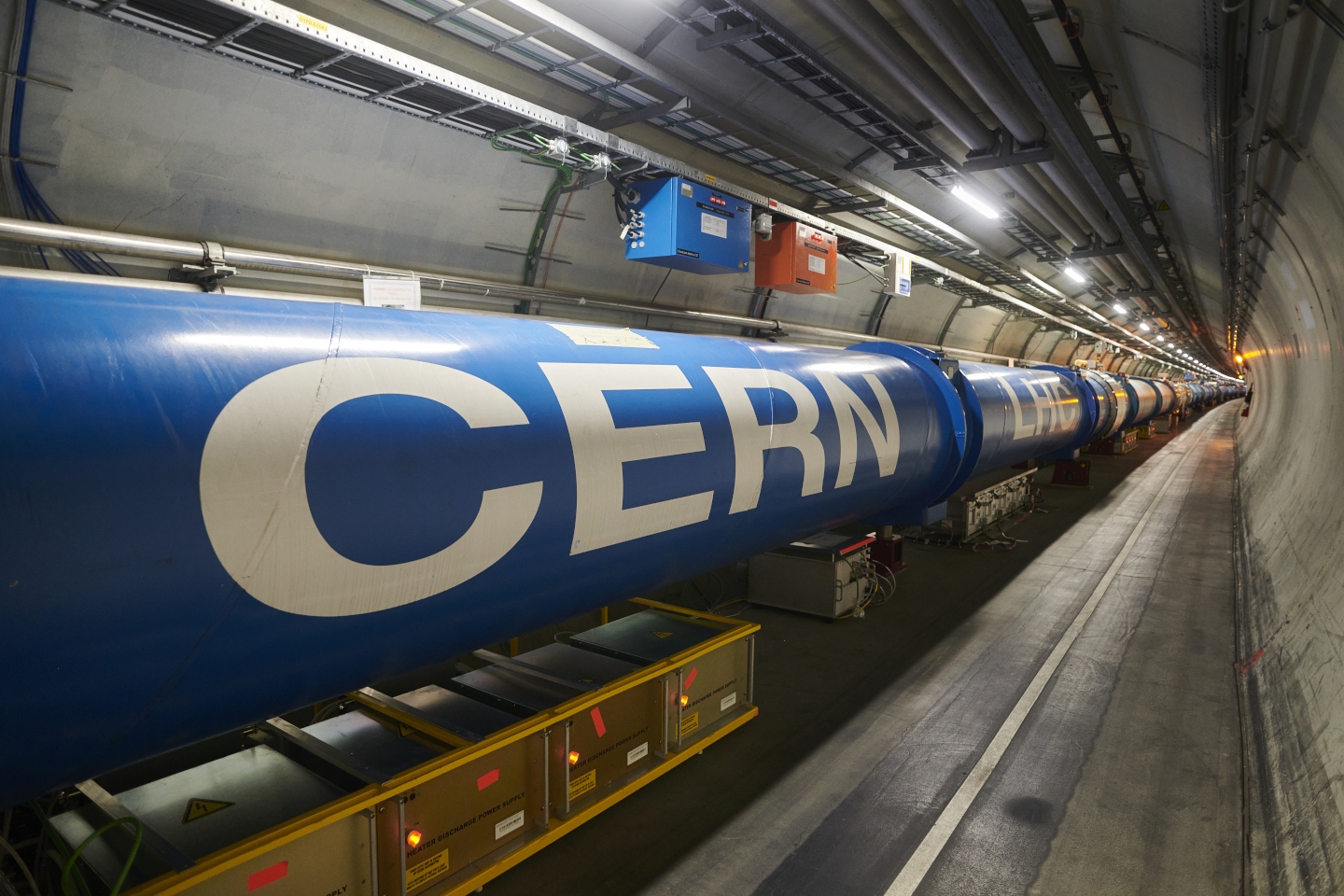

Particle physics is CERN’s main area of research, to learn more about the fundamental structure of matter using highly advanced and powerful accelerators and detectors. One such research instrument is HiLumi, the High Luminosity Large Hadron Collider (HL-LHC), which is undergoing a significant upgrade. The refurbishment will enable future experiments to gather more extensive data samples and acquire incredible scientific research results. This major project is currently undergoing the phase of procuring and testing the cable products, with the project due to commence installation in 2025 and launch in 2029. The development is expected to use approximately 2,000km of cables. In addition to the HiLumi project, CERN facilitates several other experiments and research areas, such studying dark matter and producing 3D colour X-rays, to name a couple of examples.

Image source: copyright © 2023 CERN

A comprehensive selection of cable products is used across the CERN research facility, spanning over 420 different cable products. Many cables are designed bespoke to meet radiation requirements HSE 500 kilo Gy(Gray) and up to 10M Gy. Cable types used include Low voltage, Medium Voltage, High Voltage, Multi-core, Fibre, Single Core, Low Smoke Zero Halogen, Telecommunication cables, Coaxial cables, Control cables, and Special cables.

Quality to enhance safety

Safety is crucial to CERN, to protect the people and the infrastructure involved with all research projects throughout the facility. Ensuring the cable products providing power, communication, and data can evidence high levels of quality helps to support the safety of the applications to demonstrate compliance and performance. The behaviour of the cables themselves is vital, so CERN can source and implement efficient cabling systems that have been tested to determine properties such as mechanical and electrical. The goal of gathering as much data as possible and extracting it from the instruments is vital and relies on the cables to perform efficiently.

Handling the cables is a critical process for CERN, as they must be pulled down approximately 100 metres in the case of the Large Hadron Collider. An extensive amount of planning is involved with preparing and installing the projects. Therefore, a failure with components such as cables can result in a high monetary and time loss.

The cost of replacing a substandard cable is far greater than procuring high-quality cables that will perform safely and efficiently.

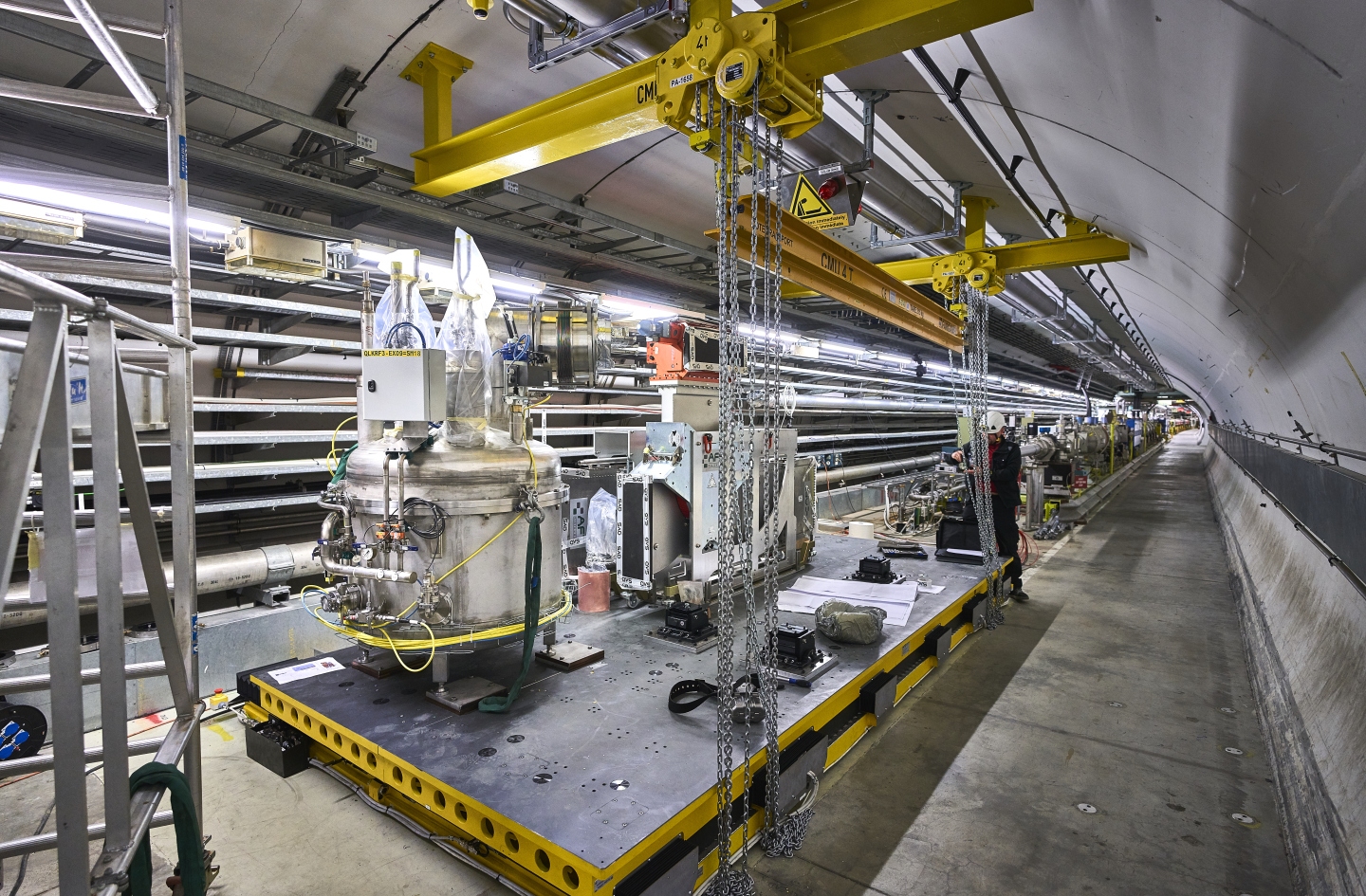

Image source: copyright © 2023 CERN

To determine the performance of the cables chosen for installation, BASEC as a third-party testing partner, supports CERN by conducting rigorous tests. The assessments measure the properties of the cable, including electrical, chemical, mechanical and material, to ensure that quality is not compromised.

Sondre Flateraaker, Quality Assurance Coordinator at CERN comments:

“Safeguarding progress with quality cables supports in powering the forefront of particle physics research at CERN”

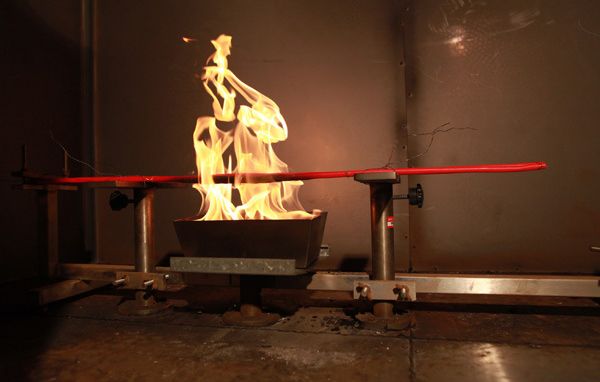

Impact of CPR

A challenge that CERN often finds when sourcing suitable cables for their projects is being able to obtain cables that meet their specific requirements. The nature of the research that CERN carries out means that the cables must have radiation-resistant compounds. In relation to CPR, the mixing of fire behaviour compounds with radiation compounds can prove challenging to achieve the desired classification. As a result, cable modifications have been required such as producing larger, thicker cables which creates a new dilemma with circuit components such as connectors. It is important that the cables undergo rigorous testing to ensure that they would not accelerate flame spread in the event of a fire.

CERN’s Specific Safety Instructions (SSI-FS-2-1) sets out the fire safety and radiation resistance requirements for cables. For High Risk Installations the fire performance according to the Construction Products Regulations (CPR) shall be at least Cca-s2,d1,a2 and for Low Risk Installations at least Dca-s2,d1,a2.

Value of third party testing

When searching for a third party testing provider, there is a balance of country providers that CERN sources from across the member countries. The company’s reputation is critical, particularly that the organisation is knowledgeable and can provide the specific testing capabilities necessary to meet the requirements. Using a third party such as BASEC for cable testing provides independent verification that the cables have been stringently tested to meet the requirements for transparency and peace of mind. This allows CERN to have confidence whether cable is suitable and fit for purpose to install within their projects.

Sondre Flateraaker, Quality Assurance Coordinator at CERN comments:

“Empowering confidence and compliance, BASEC’s third party testing ensures cables meet CERN’s stringent requirements for safety and performance.”

Download a copy of the case study below.

To find out more contact the team today

Banner Image source: copyright © 2023 CERN