Why a comprehensive assessment is key to testing new cable designs

Cable testing is essential to measuring conformity to regulations, quality and functionality of product, it also ensures successful performance in end applications.

Which tests should you request, in relation to newly developed cable products? Read more about test standards and methods for new cable designs, including data communications cable types where performance characteristics such as transmission must be closely monitored, and consider programmes tailored to verify bespoke cable designs awarded with a CAD - Certificate of Assessed Design. Learn why complete cable assessments, which test for a range of properties helps you gain a holistic understanding.

Verifying quality through cable testing

Cable faults and failures can be incredibly costly to repair or replace, in addition to this they also disrupt day to day operations which can impact an organisation’s reputation and customer loyalty. Similarly, it is vital to take precautions to minimise the risk of faults in order to protect the safety of users. Careful considerations must be made at the cable design and manufacturing stages to ensure it meets the relevant standard’s requirements a full suite of testing including mechanical, electrical, fire, chemical, and smoke for LV, MV, HV and data cable variants is undertaken. In undergoing stringent testing procedures, quality and conformity can be evidenced. This in turn brings peace of mind to specifiers, installers and end users across the supply chain that the cable products are fit for purpose to operate reliably and safely.

Evolution of technology

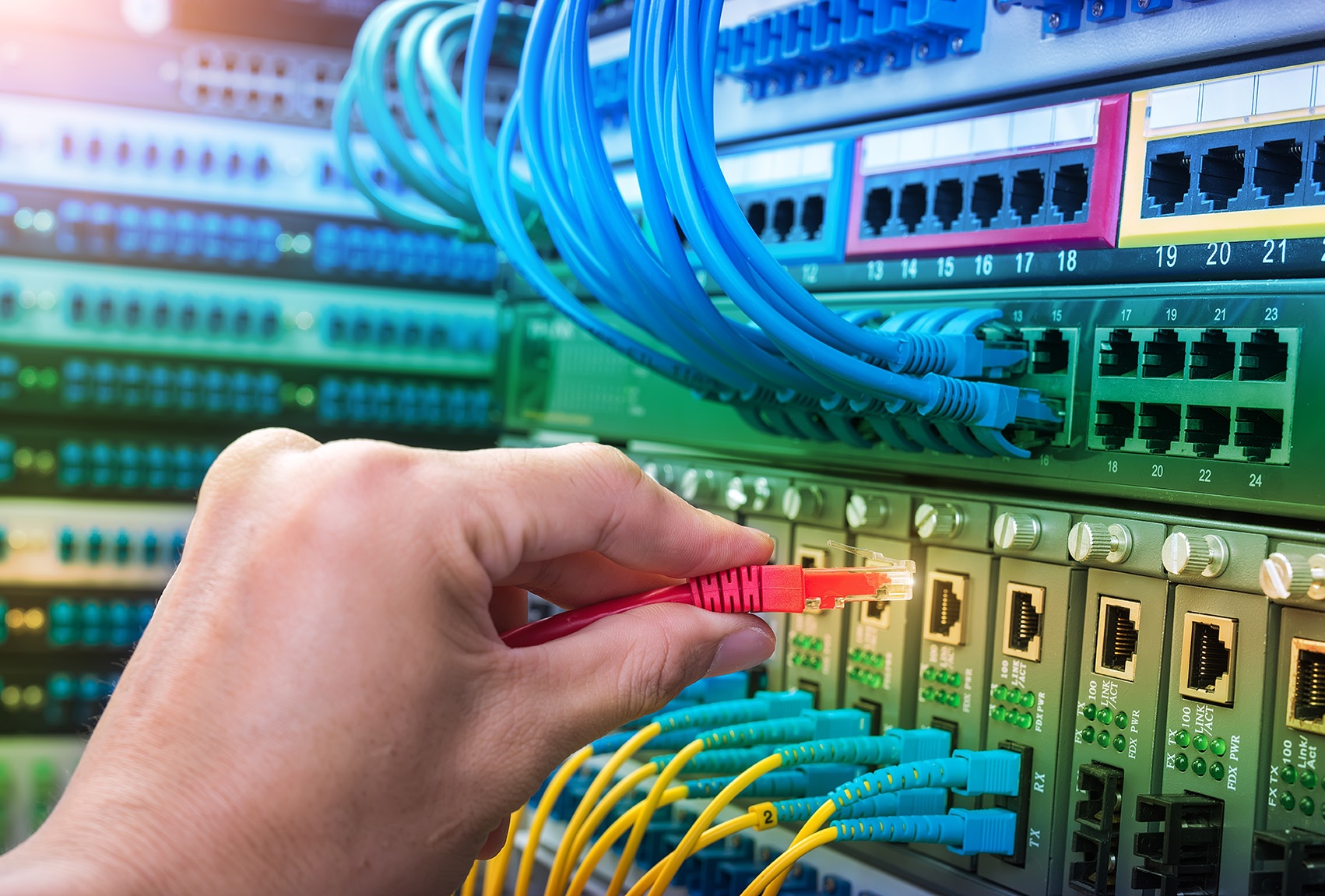

There is no doubt that digital technologies have developed at a phenomenal rate over recent decades. To support this, the capabilities and characteristics of data communications cables have also had to evolve in order to process greater amounts of data at faster rates. Transmission speed is one factor that has changed dramatically, which has been impacted by the advances in ethernet connectivity within local area networks, commonly known as LAN networks. It is also important to test for signal interference as this assesses whether the flow of data transmission is experiencing any crosstalk, which can lead to reduced signal quality, offering the potential to cause errors. To minimise this risk the use of high quality, shielded cable products is recommended. Shields are used to reflect signal interference pushing it in the opposite direction or conducting it to the ground.

Cable categories have expanded as a result of the demand for higher network speeds. Separate categories provide a clear definition of the performance a cable is designed to demonstrate, in relation to both transmission speeds and distance. Tiers range from CAT5e, which supports enhanced crosstalk gigabit network specifications, through to CAT 8 cables, which are primarily used within data centre locations and are specifically designed to support data rates up to 40GB/s. The CAT 7A cable type is most commonly used within cabling infrastructures for high speed enterprise networks across European markets at 1000MHz.

Digital technologies demand efficient cable products for high speed networks

Holistic data communications cable testing methods

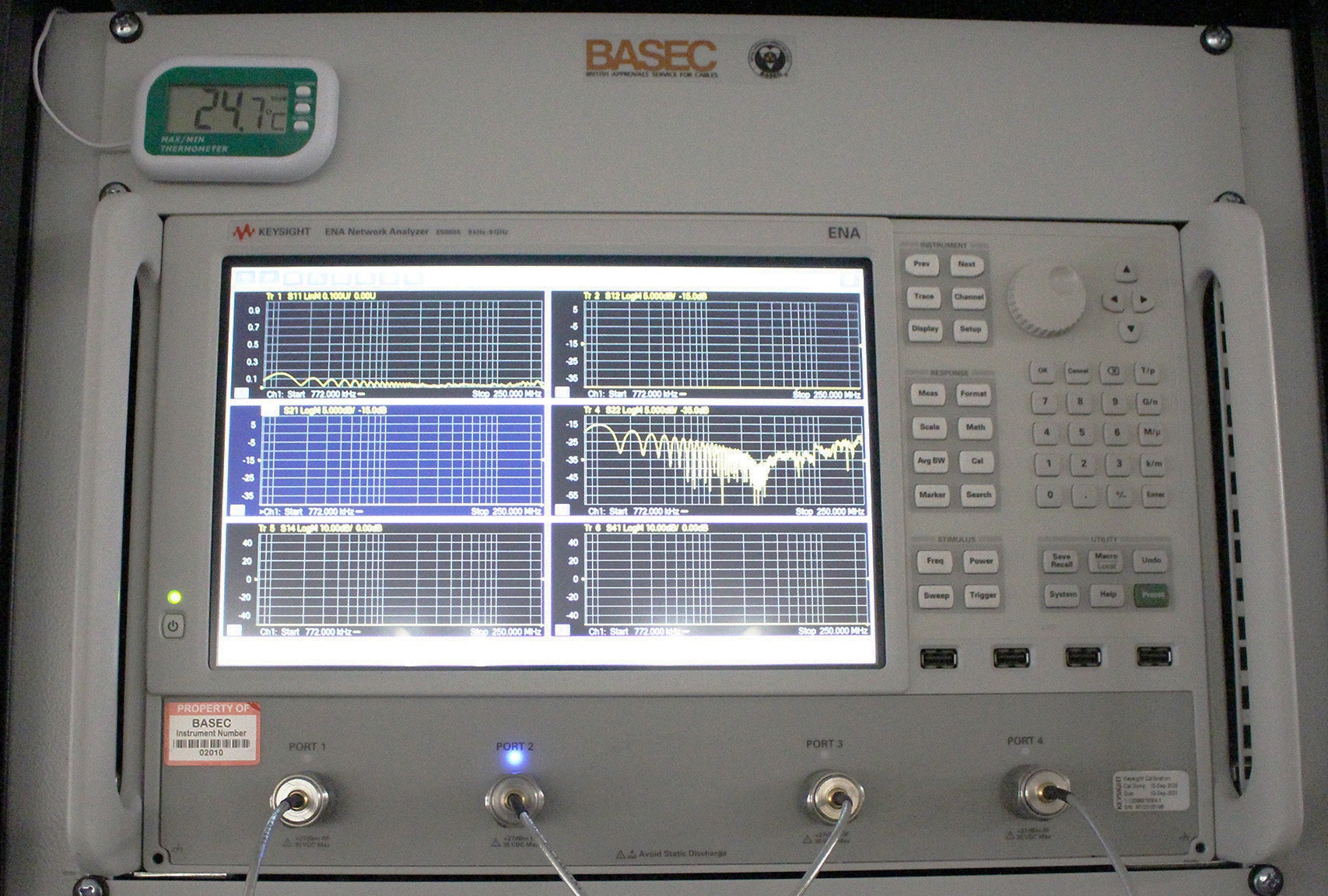

Data communications cables must comply to widely recognised standards, including the BS EN 50173 European standard, which is applicable to cable systems for a variety of environments from offices and industrial buildings, to residential units and data centres. In addition, the ISO 11801 International standard outlines cabling infrastructure requirements such as the distance, installation methods, link and channel performance as well as outlining the testing requirements for generic telecommunications cable products.

To gain certification, a complete cable assessment covering a range of test areas is undertaken to reinforce the safety and reliability of the data cable being appraised. Precise testing of cables in links and channel configurations, offers the beginnings of integrated systems testing which helps to determine that the cabling can support the network setup and speeds required to transmit data. The testing of pair balance is also a crucial element and is measured through the assessment of unscreened cables in tough, simulated electromagnetic heavy environments.

Reaction to fire properties must be considered in relation to data cables as the majority of products feature polyethylene compounds, and this presents a fire risk, as these cables are installed in large bundles within buildings. Testing to include flame propagation, smoke emissions and acidic or corrosive fume assessments are undertaken for all cable types as well as those with low smoke, halogen free properties. As data cables can also be exposed to several harsh environmental conditions that could affect performance once installed, mechanical and material tests are important. These include cold bend, tensile strength and elongation at break to assess the durability of the cable construction, in particular the sheathing and insulation materials.

Specialist data communications testing equipment at the BASEC laboratory

How to get bespoke and hybrid cable designs to comply, and what is a Certificate of Assessed Design?

When considering cable products for specific applications, there are occasions when an off the shelf product does not offer the performance characteristics required, and thus a bespoke design is the most suitable option. This often occurs when a new form of technology requires the development of a new cable design to support its function. In this scenario, there is often no established national or international standard in existence for the product to comply to. It is at this point a CAD, or Certificate of Assessed Design, may be the best solution as it is designed to assess the complete cable along with any tailored design features to provide evidence that the cable is able to meet industry level safety and performance requirements.

Working together with the cable manufacturer, an initial test plan is devised to verify the performance and safety of the product, outlining which initial type tests are to be undertaken in order to gain certification. Ongoing surveillance is also then carried out to ensure continued levels of quality are met, this is achieved through the submission of a minimum of 16 cable samples on an annual basis for testing. The aim of a CAD is to bring peace of mind to the manufacturer and third party testing assures end users of product quality. Once a manufacturer has gained a CAD a unique BA reference number is provided, based on industry demand this can in time be used to become a BS or IEC standard in its own right. An example of this is the in-house developed range of control cables specifications launched in 2019 which is in the process of British Standard adoption.

Key points

Implementing a comprehensive assessment to the testing process of new cable designs, such as data communications cables, minimises risk of costly faults which may occur during manufacture or installation. Stringent testing procedures assess a variety of performance characteristics in line with existing standards or tailored to incorporate industry level comparisons to ensure products are compliant. In cases where bespoke cables are developed a CAD, or Certificate of Assessed Design, provides confidence that cable products have been rigorously assessed. Access world class laboratory facilities at BASEC, equipped to provide complete cable assessments, with a newly opened, dedicated data communications test centre.

Engage the BASEC team of experts today to learn how to take your next steps to gaining data communications certifications, or to enquire about obtaining Certificates of Assessed Design.

Download your free copy of the data communications testing guide below.