Control Cables Certification Case Study: Unka Kablo

Unka Kablo is a low voltage cable manufacturer, mainly focused on flexible control cables and instrumentation cables. Based in Turkey, they are the first manufacturer to gain control cables certification with BASEC. The vast majority of their products, 98% in fact, are exported globally to more than 30 countries, mainly to their key markets including the UK, Germany and East Asia.

Established in 2005, Unka Kablo’s facilities have been designed with improving quality processes in mind. The main cable products manufactured, include both: low voltage power and control, instrumentation cables for use in a wide variety of end applications. Unka Kablo strives to continually improve their products and processes, supported by ongoing auditing conducted by BASEC as part of their product certification assessments. The team at Unka Kablo also aim to provide a customer focused service. This powerful combination, Unka Kablo believe, helps to set them apart from their competition. Baris Tabak, Quality Assurance Manager at Unka Kablo comments “Our company vision is to be perceived as a reliable, trusted brand of cables, we aim to achieve this by supplying our customers with high quality products that are produced to last and endure their end applications”.

Design is Key

Control cable products, commonly known as YY, SY and CY, are required to be flexible and are typically used on assembly or production lines. The design of these control cable products was a vitally important part of the process to gaining control cables certification with BASEC. With such a diverse range of control cable compounds available, Unka Kablo had to make sure the right combination of properties, determined by the raw materials selected, were present in the cable. Material choices were crucial to ensuring high levels of quality and performance could be achieved.

Rigorous testing of the materials, mechanical properties, fire performance and for any electromagnetic interference protection capacity, are involved in the certification programme. These assessments are vital to ensuring the cable, being verified, can withstand forces such as heat, pressure and bending, whilst still continuing to perform or operate as intended.

To meet the specification requirements, BASEC has worked to develop the standards to a generally, higher specification when compared to control cable designs currently found on the market. Unka Kablo were particularly interested in this aspect of the scheme, enabling them to work towards bettering product quality.

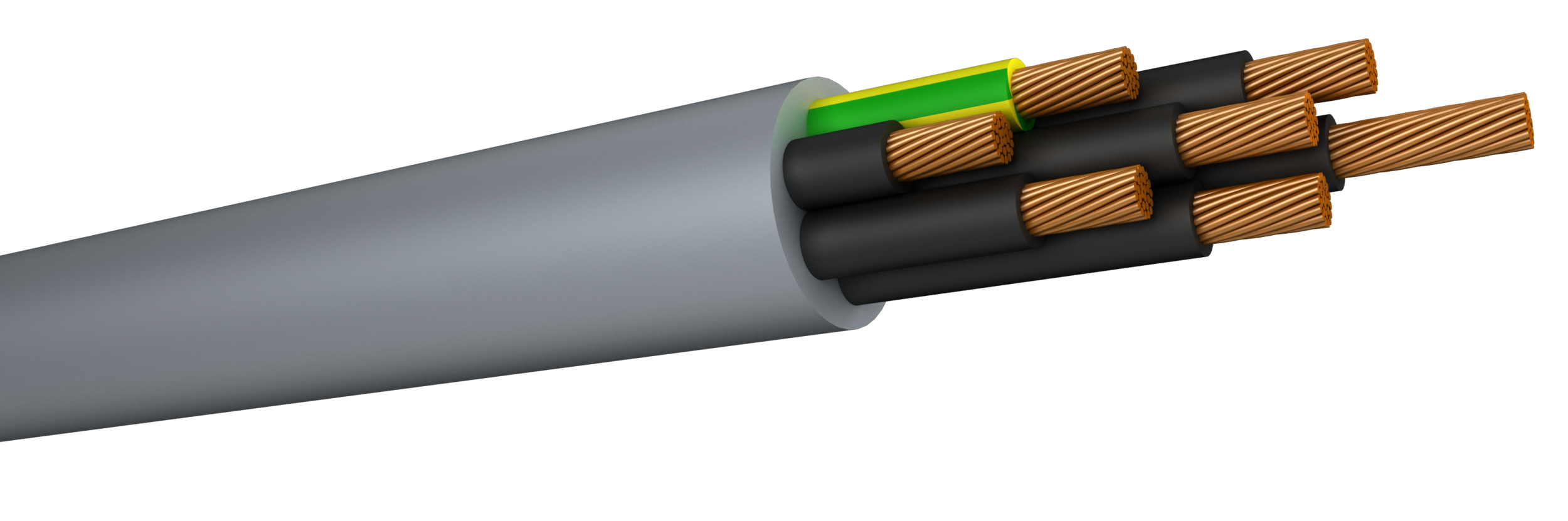

Unka Kablo's BASEC approved YY control cable product

Unka Kablo's BASEC approved YY control cable product

Gaining Competitive Advantage

Unka Kablo were one of the first cable manufacturers based in Turkey to gain CPR approval, which has helped to demonstrate their commitment to improving quality assurance and safety. Their decision to gain control cables certification supports the company’s challenge to innovate via proven cable products.

Certification presents the control cable industry and its users with the ability to benchmark consistent levels of quality. Enabling specifiers, buyers and installers to access a range of standardised and comparable products in the market.

Baris Tabak comments “We have partnered with BASEC as they are recognised in industry as the experts in cable testing and certification. As a business, Unka Kablo is committed to providing our customers with products that can be proven to meet high levels of quality. Control cables are an important part of our product offering and we are keen to emphasise the importance of this certification, as it allows us to access international projects and markets.”

As a result of certifying their control cable products to BASEC’s specification, Unka Kablo predicts the control cables compliance will help them to differentiate their products. Third party approval allows them to access supply opportunities into highly automated infrastructures, which require reliable products, helping Unka Kablo to proudly position themselves as better, when compared against lower quality, or non-standardised control cable products.

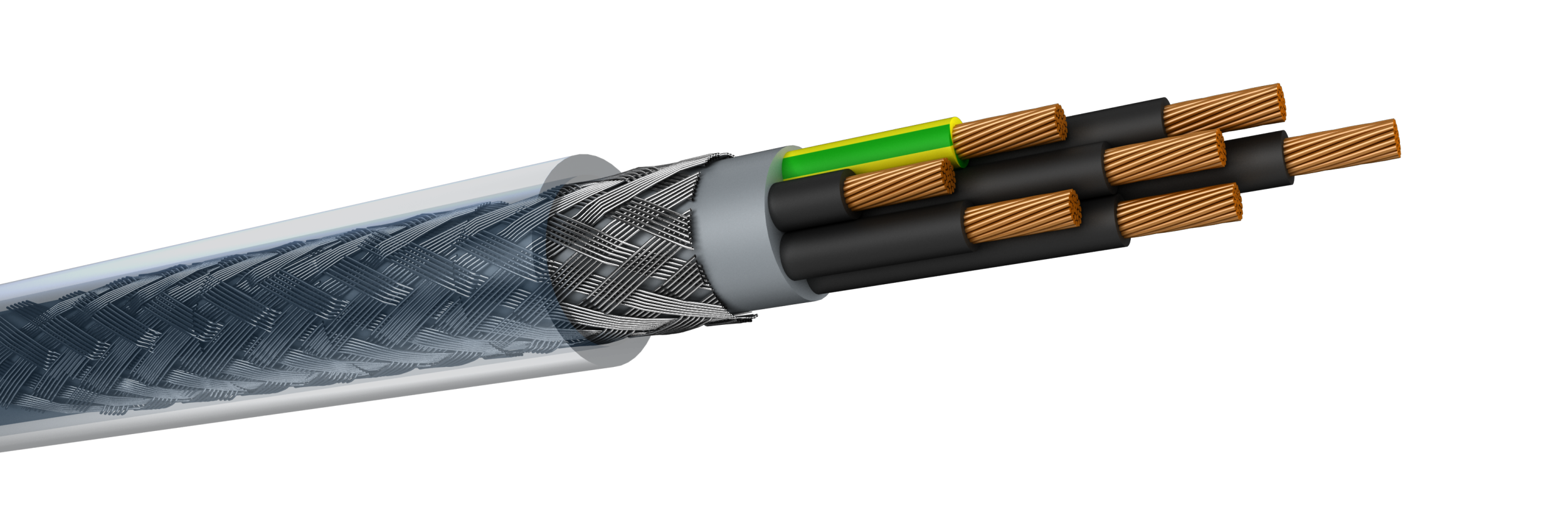

Unka Kablo's BASEC approved SY control cable product

Unka Kablo's BASEC approved SY control cable product

Prioritising Safety

The control cable certification scheme is available for cable products up to and including 300/500 V, which have a maximum conductor operating temperature of 70°C and include both PVC and LSHF compound options. Certification contains a comprehensive testing schedule, which rigorously monitors and assesses the cable products. The test programme includes electrical testing on both the complete cable and individual cores, constructional and dimensional tests to check thickness measurements and as a special measure the braiding coverage percentages for CY and SY types are also reviewed. Material and mechanical tests are also undertaken measuring factors such as tensile strength, pressure at high temperature and elongation at break. Finally, fire testing is also carried out in the form of a single flame propagation test, to check flame spread for PVC control cable types, separately smoke density and corrosive gas emission measurements for LSHF control cable types are taken.

Gaining certification from BASEC for control cables evidences the ability of cables to perform in line with cable industry parameters and enables end users to be clearer on the design of these cables when specifying or sourcing them. Approved manufacturers gain advantage over their competitors as their commitment to quality helps to sets them apart in the market. Approved cable certification highlights verified and credible control cable products.

To enquire about where you can purchase control cables holding a valid product certification contact BASEC now!

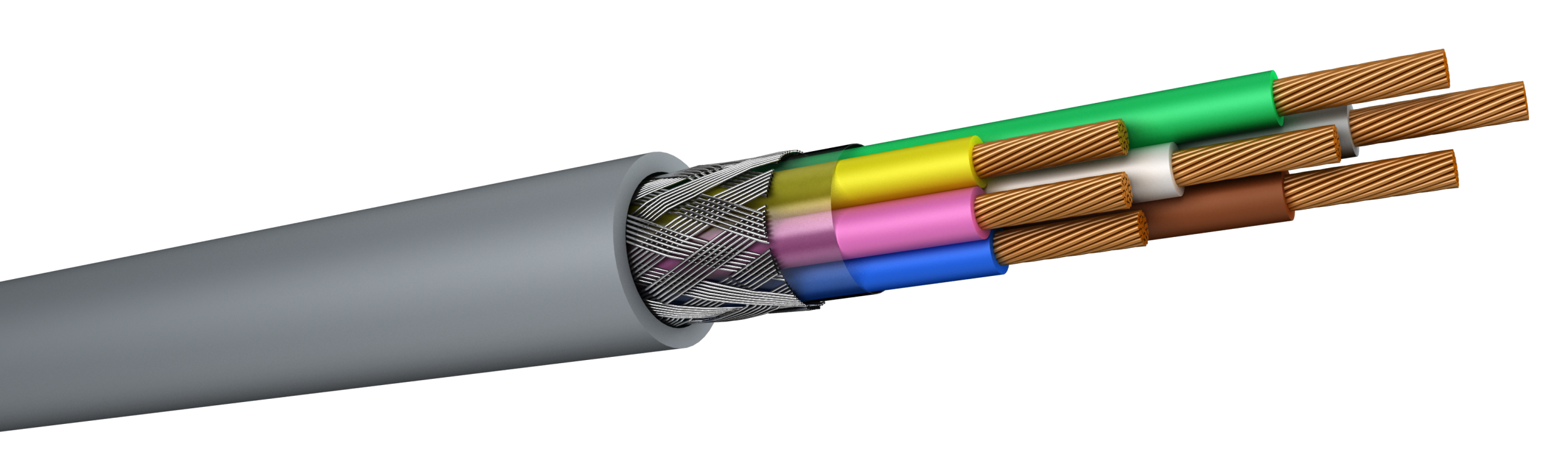

Unka Kablo's BASEC approved CY control cable product

Unka Kablo's BASEC approved CY control cable product