Prepare your cable for harsh industrial environments

Learn why mechanical, ingress, chemical and electromagnetic (MICE) categorisation, where specific testing to assess performance in industrial environments, was introduced and why using independently approved data cables will become increasingly more important as industries migrate to increased digitalisation.

There has been a rise in ethernet demand within harsh industrial environments with surroundings not typically found in commercial offices. This has prompted the introduction of MICE categorised testing and certification solutions. Cables can experience many different scenarios within MICE classified conditions, for example the risk of being crushed or exposed to solvents all of which can impact the performance of your data cabling systems and compromise or affect the integrity of your data transmission.

The market

The Global Industrial Ethernet Market Research Report published in September 2020 forecasts that the industrial Ethernet market is due to grow to around US$ 70.9 billion by 2025 (23% CAGR).

This market growth is driven in no small part through the concept of the Industrial Internet of Things (IIoT) or Industry 4.0. Whilst both concepts are aimed at improving efficiency and productivity the terms, IIoT and Industry 4.0, are used interchangeably which is not always accurate.

The concept of IIoT distinguishes itself from the commercial concept of the Internet of Things (IoT) in that it describes how manufacturing devices connect to internal networks and the global internet.

Generally, Industry 4.0 refers to the developments and innovations realised through connected devices supported by massive computing power to enable automation. In turn, this drives lean, efficient manufacturing and process operations. In a simple sense IIoT is a component of Industry 4.0, without which the connectivity and data sharing realised through the IIoT Industry 4.0 would not exist.

The eventual migration of IIoT networks to IP/Ethernet is a given, but it is important to recognise a major factor unique to this transition. Ethernet standards, components, including cabling and systems designed for Local Area Networks (LANs) are not a natural fit for IIoT networks.

Traditional LAN cabling products in the market today, which comply with the requirements of ISO/IEC 11801-2, EN 50173-2 and ANSI/TIA 568C.2 have been designed for the benign environment of the office. They are unlikely to meet the more rigorous conditions required in industrial settings. Cables and cabling will have to therefore, be more robust. Cabling products need to be specifically designed and tested to ensure their reliability and are adequately classified for these more challenging environments.

Cabling standards for the industrial environment – an overview

Traditionally, the industrial cabling market has been supported by several Ethernet enabled, bus solutions such as Profinet, EtherNet/IP, EtherCAT, Modbus-TCP. Often functioning as either standalone networks or requiring a gateway to enable the integration with corporate LAN’s. The ability to transmit large volumes of data to and from many connected IP enabled devices presents a challenge: can the network’s bandwidth, afforded by traditional fieldbus systems, effectivity match the system’s output needs? A perceived lack of bandwidth could present a barrier to increased levels of factory automation. Future cabling networks, and consequently the ongoing development of and compliance to these cabling standards, must enhance business efficiency and productivity. Helping to facilitate the key objectives of manufacturing and process automation.

Increasingly, the introduction of higher bandwidth low latency 4-pair 100Ω cabling infrastructure described within ISO/IEC 11801 is viewed as a realistic, scalable and reliable high-speed option for the industrial space. Capable of supporting data rates from 10Mb/s through 1Gb/s and up to 10Gb/s, 4-pair 100Ω cabling can simultaneously deliver up to 100Watts of DC - Power over Ethernet (PoE) affording an effective, low-cost transmission line.

Originally written to provide guidance for the installation of cabling within a basic office environment ISO/IEC 11801 was revised. In 2017, ISO/IEC published ISO/IEC 11801-3, generic cabling for customer premises Part 3: industrial premises, it outlines architectures and planning guidance for communications Links and Channels for the industrial environment. When published, ISO/IEC 11801-3 replaced ISO/IEC 24702, which was the previous reference document for industrial networks.

In the USA, ANSI/TIA had already published TIA 1005A, which was recently re-affirmed in 2019, to address their local industrial market needs and recognise both 4-pair and 2-pair 100Ω cabling solutions.

Through the collaborative international efforts, of both the users and standards making bodies within IEC and USA, a series of environmental conditions were agreed and standardised which are now recognised under the acronym M.I.C.E.

What is M.I.C.E. and why is it important?

The original concept of the M.I.C.E. environmental classification system for generic cabling was initially introduced by the International Standards organisation (ISO/IEC) in 2007. The industrial user community together with the international standards community recognised a significant challenge had to be met before Ethernet and the 4-pair 100Ω cabling solution could be ‘fit for purpose’. The subsequent collaboration resulted in the publication of their technical report ISO/IEC TR 29106.

This document is currently published as ISO/IEC TR 29106 edition 1.2.

In the USA the same M.I.C.E. environmental concept was embraced in 2009 with the release of TIA TSB 185.

Both TR 29106 and TSB 185 seek to define four primary environmental criteria used to classify an environment, the:

- M element, defines the mechanical characteristics of the environment

- I element, defines the ingress protection characteristics of the environment

- C element, defines the climatic and chemical characteristics of the environment

- E element, defines the electromagnetic characteristics of the environment.

Each of these four primary environmental criteria are further divided into specific parameters, and various levels for those parameters.

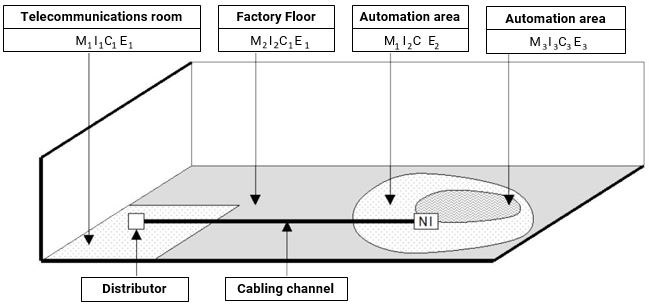

The MICE classification for a given location is therefore defined as MaIbCcEd where a, b, c and d are the individual sub-classifications levels for the M, I, C and E criteria respectively.

The suffixes used to classify the four primary environmental criteria are scaled as either 1, 2 or 3. For example, the simplest environments are described as M1I1C1E1 whereas the harshest environments, within the scope of the standard, would be defined as M3I3C3E3.

Figure 1 illustrates how the industrial environment may affect local conditions, affecting the MICE requirements of a cabling channel, as the cable traverses from the office environment through to a plant or factory floor.

ISO/IEC TR 29106:2007+AMD1:2012 +AMD2:2019

It is important to recognise that the M.I.C.E. classification requirements outlined within ISO/IEC TR 29106 are intended to supplement the planning and installation guidance given within ISO/IEC 14763-2, ISO/IEC 14763-4 and IEC 61918. Combined, they assure network performance and confidence that the installed network is fit for its intended purpose.

Are the existing cabling standards prescriptive for M.I.C.E. solutions?

Unfortunately, nether ISO/IEC 11801-3 or the associated cable standards such as IEC 61156-5 make the M.I.C.E. requirements obvious.

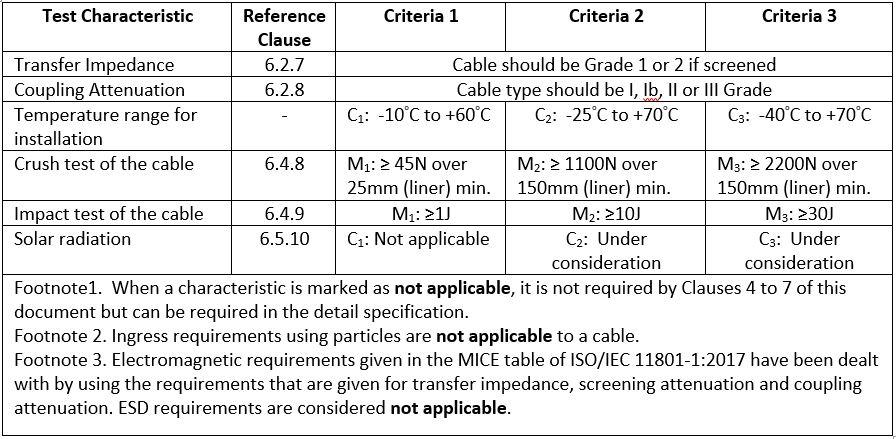

Within IEC 61156-5, M.I.C.E. clarification comments are mentioned within the footnotes of the ‘Blank Detail Specification’ in Annex A. The below extract (Figure 2) illustrates the limited level of acknowledgement for M.I.C.E. That said, within the standard’s main text, manufacturers and specifiers are referred to consult ‘the detailed specification’ with little further guidance. Frequently, some of the characteristic requirements are stated as ‘not applicable’ as can be seen below.

Simply accepting this limited reference to M.I.C.E. within IEC 51156-5, for example, without considering ISO/IEC TR 29106 could lead to a significant underestimation of full compliance with a M.I.C.E. classification requirement. As a result, this could lead to a claim of over performance.

At the time of writing, the CENELEC standards represented by the EN 50288 series do not currently reference M.I.C.E requirements for cables.

For any cabling components including cables, manufacturer’s seeking to assess and establish a M.I.C.E. rating for any products, it is recommended that reference to ISO/IEC TR 29106 is necessary for a more comprehensive listing of test criteria and requirements for each level of classification.

ISO/IEC TR 29106 raises an important point of caution.

The document indicates that in establishing a Technical Report, the work completed to determine a M.I.C.E. classification system is intended to address 80% of the environment to which cables may be subjected. Other environmental conditions will exist. It is advisable that any such environments are understood, quantified and any specific or individual testing requirements agreed before performance claims are made.

What is the role of BASEC in the M.I.C.E. classification of products?

As a testing and certification organisation BASEC recognises the future dependence and success of manufacturing and process organisations upon access to reliable data. There are a number of benefits to integrating field-generated data with higher-level management systems to reduce production costs.

The team at BASEC believe that reliably integrated data helps to enhance the potential for automation, whilst maintaining or even increasing the quantity and quality of production. A correct network installation, which uses independently tested and verified M.I.C.E. cabling and components, is an important prerequisite for communications. It enables greater process availability and consistent performance.

Assessing and classifying the environmental aspects of products, such as their mechanical, liquid, particulate, climatic, chemical or electromagnetic interference, requires a specialised skill, competence and test facilities.

BASEC is an established, independent testing and certification laboratory renowned for testing and accrediting manufacturers’ systems and their cabling products for use in difficult environments.

Capable of supporting the testing requirements outlined within ISO/IEC TR 29106, or client specific requirements, BASEC believes that it is uniquely placed to support the independent classification of cabling products for the likely challenges of the IIoT and Industry 4.0 markets.

Application considerations – what next?

The demand for data will continue to increase as we go through a continually evolving ‘digital transformation,’ with the industrial, process and building automation adopting adopting data driven technologies, more companies need to consider the MICE classification to assess the potential implications for the cabling deployed within their working environment.

Traditional LAN cables are developed for the office environment and would be routinely classified as M1I1C1E1 It is unlikely therefore that this standard of cabling would be ideally suited for more rigorous industrial settings.

In order to make this assessment you should assess and categorise your industrial operating facilities in accordance with IEC 61918 to benchmark its MICE classification requirements now! The cables you need to use, should meet the individual MICE attribute classification level prescribed for the environment. The specification of tried and tested, third party approved data cables matched to operate in your industrial setting, will enable you to comply with industry standards, and in turn improve business efficiencies and productivity.

Industrialised settings require higher performance levels, and thus higher quality components including cables, to ensure they can operate as efficiently, if not more so, than their counterparts designed for the benign environment of the enterprise.

In industrial and process automation environments the impact of cable failure can be significantly more detrimental to your business. Steps should therefore be taken to use data networking cables of a highest levels of quality, tested and certified in line with a MICE classification. Gain peace of mind that your cabling infrastructures are reliable and can efficiently transport data without any signal loss risks.

For more information about data communications cable testing and certification, which includes MICE testing contact the BASEC team now or download our data communications guide