New testing and certification scheme launched for YY, SY, CY control cables

In response to direct demands from the marketplace, BASEC has launched a certification scheme to encourage standardised and consistent levels of quality for control cable product ranges, known as YY, SY, CY.

As an authority and preferred testing and certification partner to the worldwide cable industry, BASEC is regularly contacted to support and advise on control cable products comparability and application.

Our new scheme offers the cable industry and its users a way to improve and evidence the levels of quality and safety that the products manufactured, specified or sourced hold. There is presently no referenceable standard in existence, hence the reason these cable products are often a debated hot topic.

The scheme comprises of 6 BASEC specifications BA 1411, BA 1413, BA 1415 for PVC composition and BA 1412, BA 1414, BA 1416 for LSHF composition.

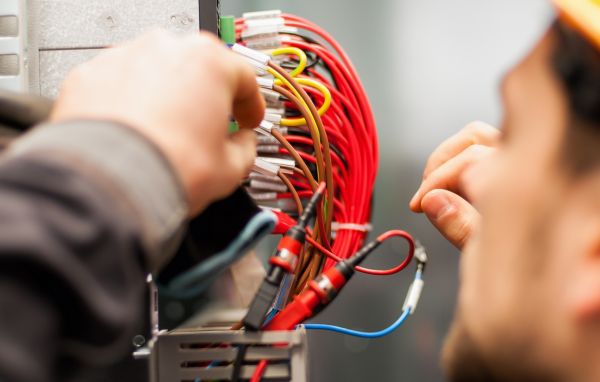

Control cables are found in a vast array of industries, across many industrial and everyday applications. These products are flexible, interconnecting and used to measure, control or regulate equipment on assembly or production lines, as well as supporting their associated computer units and work processes.

The new certification scheme is relevant to cable products up to and including 300/500 V, with a maximum conductor operating temperature of 70°C. Standards EN 50525-1 and EN 50565-2, where applicable, will be referenced in conjunction with the control cable scheme document.

BASEC is known within the industry for rigorous certification, factory auditing and testing schemes, which work continuously to improve quality and safety of cable products at manufacturing source. It is with this in mind, that the scheme has been developed, offering an all-inclusive testing programme for this widely used and barely regulated range of cable products. The below summary provides an insight into the depth of the testing which will be undertaken, which will in turn raise the levels of consistent quality in the market.

Testing schedule summary:

- Electrical testing

- Voltage testing on complete cable and cores

- Resistance testing of conductor, insulation in normal and long-term scenarios and surface of sheath

- Transfer impedance on copper screened variants

- Constructional and dimensional tests

- Compliance with constructions

- Thickness measurements of insulation and sheath

- Overall dimensional checks

- Mean value and ovality

- Material and mechanical tests on insulation and sheath

- Properties before aging

- Properties after aging

- Tensile strength

- Elongation at break

- Loss of mass

- Heat shock testing

- Pressure at high temperature

- Bending and elongation at low temperature

- Impact testing at low temperature

- Complete cable mechanical strength

- Fire testing

- Single vertical cable flame propagation, to check flame spread characteristics

In 2016, a BASEC original scheme specification BA 1200 developed for single core fire resistant cables, based on market demand, was incorporated as a BS standard. Now BS 8592 as we know it today. Our longstanding tenure as a leading testing and certification provider and technical authority leads us to expect this new control cable scheme to hold the same potential – a vehicle to increase standardised levels of quality and safety.

Contact your local Commercial Manager today to discuss your requirements