Data integrity at high speeds - why data cable design is integral in data reliability and speed, and why product testing is critical in assuring this

In today's digital age, data integrity and speed are essential requirements in various fields, including healthcare, finance, and telecommunication. Organisations depend on the accurate and timely delivery of data to make informed decisions, optimise processes, and stay ahead of their competitors. However, the reliability and speed of data transfer are only as good as the infrastructure that supports it. This is where data cable design and product testing become critical components in ensuring data integrity at high speeds.

Data cable design involves the creation of physical pathways that facilitate the transmission of data between two devices. The quality of the cable design has a direct impact on the performance of the network. Inadequate cable design can lead to data corruption, signal interference, and slow data transfer rates. Therefore, it is essential to invest in high-quality cables that are designed to meet the demands of high-speed data transfer.

One of the critical considerations in data cable design is the choice of cable type. There are several types of data cables available, including coaxial, twisted pair, and fiber optic cables. Each cable type has its advantages and disadvantages, and the choice depends on the specific application. For instance, coaxial cables are excellent for high-frequency applications, while twisted pair cables are ideal for Ethernet connections. Fiber optic cables, on the other hand, offer high bandwidth and are suitable for long-distance data transfer.

Another critical aspect of data cable design is the quality of the materials used. High-quality materials, such as copper or aluminium, provide good conductivity and signal transmission, while low-quality materials can cause data loss and signal degradation. Additionally, the design of the cable jacket and shielding can impact the cable's resistance to interference from external sources such as electromagnetic interference (EMI) or radio frequency interference (RFI).

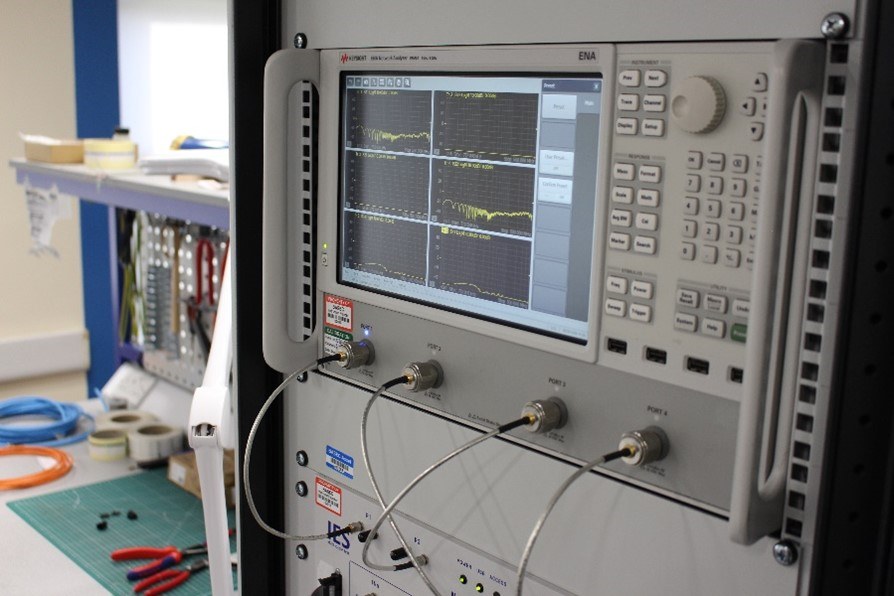

Product testing is another critical component of ensuring data integrity and high speed in communication cables. The testing process involves subjecting the cable to various conditions to assess its performance and reliability.

Some of the key tests conducted on data communication cables include the following: Bandwidth testing, Attenuation testing, Crosstalk testing, Signal-to-Noise Ratio (SNR) testing, Impedance testing and Connector testing. In addition to these tests, some manufacturers also conduct environmental testing, which involves subjecting the cable to extreme temperatures, humidity, and vibration to simulate real-world conditions.

Testing is a critical aspect of ensuring the reliability and speed of data communication cables. Proper testing helps identify any weaknesses or areas of improvement in the cable design and ensures that the cable meets the required standards for high-speed data transfer. By investing in high-quality data communication cables and rigorous testing, organisations can achieve faster and more reliable data transfer rates, enabling them to make informed decisions and stay ahead in the market.

One of the critical tests conducted on data cables is the bandwidth test, which measures the cable's capacity to carry data. The bandwidth test helps determine the cable's maximum data transfer rate and ensures that it can support the required bandwidth for the intended application. Other tests include attenuation testing, which measures the loss of signal strength over the length of the cable, and crosstalk testing, which measures the interference between adjacent cables.

Third-party testing is vital in data communications for several reasons. Firstly, it provides an impartial assessment of product quality and performance. This ensures the testing process is fair and reliable, and the product's performance claims are validated by an objective and credible authority. Secondly, third-party testing is often more rigorous than in-house testing, resulting in a more accurate and reliable assessment of product performance, essential for ensuring data integrity and reliability. Thirdly, independent testing helps build trust and confidence among customers, partners, and other stakeholders. Finally, third-party testing can help ensure regulatory compliance, reducing the risk of non-compliance and associated penalties. Manufacturers should consider third-party testing as an integral part of their product development and quality assurance process.

In conclusion, data integrity and speed are essential requirements in today's digital age, and data cable design and product testing are critical components in ensuring their reliability. High-quality cable design, combined with rigorous product testing, can help organisations achieve faster and more reliable data transfer rates, enabling them to make informed decisions and stay ahead of their competitors. As technology continues to advance, investing in high-quality data cables and product testing will become increasingly important to ensure the integrity and speed of data transfer.

To learn more about testing and certification for data communications cables download your free guide.