See the new data communications laboratory

The rapid adoption of the internet and increased use of data powered devices in industrial environments is creating dramatic growth in demand for voice, video, and data transmission. Meeting that demand is becoming progressively important but requires major upgrades to the cable networks. Cables are now required to carry out powerful transmission capabilities, whilst withstanding harsher environments than cables would typically be used to. Read on to discover predicted market trends within the data market and which tests can be carried out by a third party approval body to protect infrastructure and safeguard product quality to support a digitalised future.

Determining data cable requirements for the end user

Technology is moving at a fast pace; a cabling infrastructure must therefore match the needs of the end organisation. This of course will differ depending on the type of the business. For example, an office environment with training and conference rooms will require fast internet speeds, and, a secure building such as a bank would requires reliable automatic entry points controlled by smart devices. Manufacturing or automotive plants are also opting for smart machinery and these environments require industrial grade cables, where a cable’s outer sheath has been designed to cope with extreme environments.

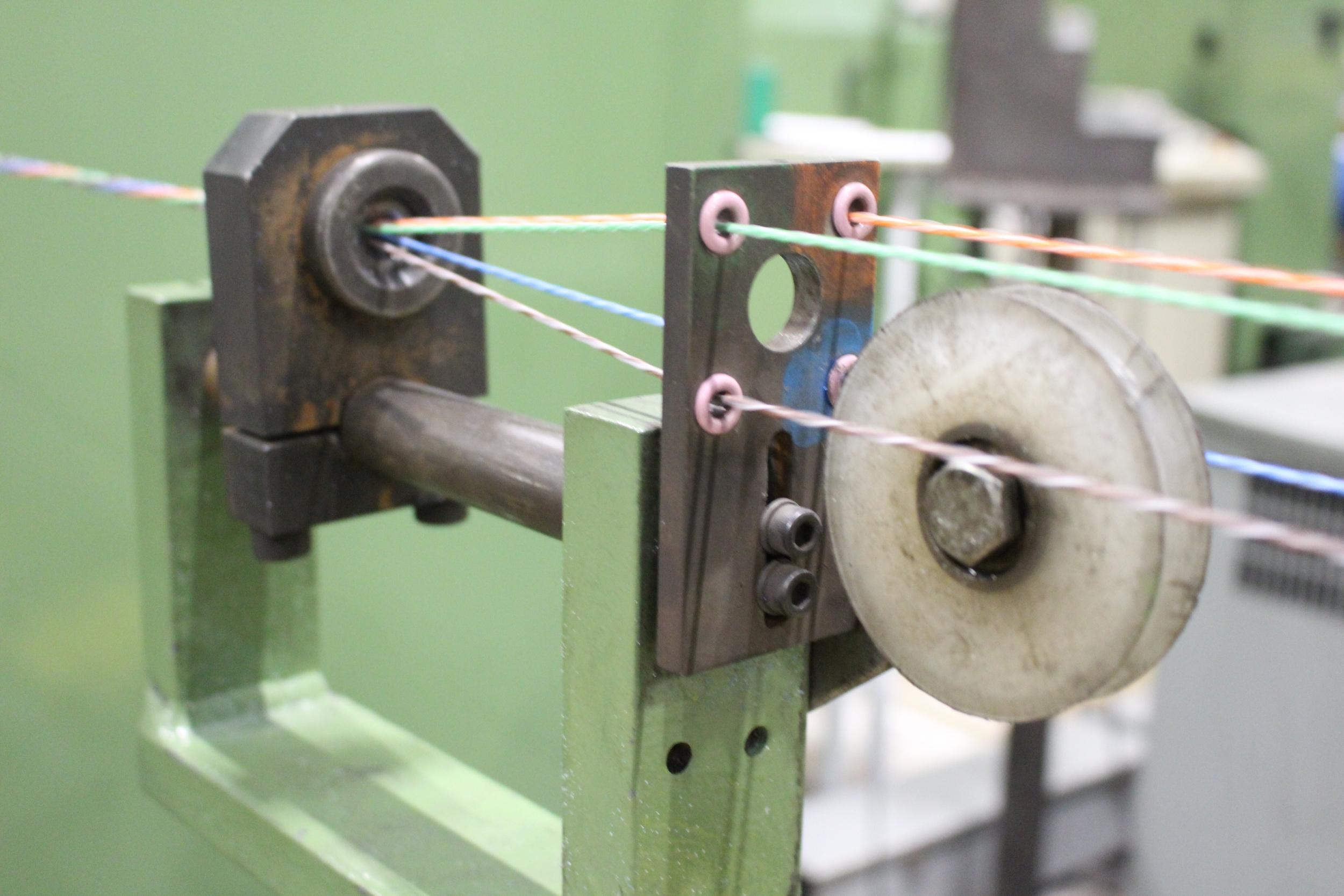

Manufacturing process of a four pair data cable

Throughout a cable’s time in service there is a range of potential causes as to why a data cable may fail including:

- Ageing - the life of a cable can be significantly reduced if it is used outside of the conditions it was designed for. Premature ageing usually results in cracking and eventual failure of sheathing materials, exposing the conductor, leading to power outage or even an electrical fire

- Application - if the wrong types of cables are used for end applications, they are more likely to fail, for example, a data cable that is not robust enough for a manufacturing environment. This could be due to the cable not being mechanically tough enough for wear and tear, or chemically resistant enough from potential spills

- Mechanical failure – as data cables are bundled together during installation it is common for them to be inadvertently damaged either during installation or in subsequent use, which can affect the integrity of the cable and reduce quality

- Cable sheath - there are several reasons as to why the sheath may become compromised, including excessive temperatures and weathering leading to electrical failures, due to the conductors no longer being protected

- Heat - excessive heating can cause premature failures due to the degradation of insulations and sheaths. A cable can heat up both from external sources, such as nearby machinery, or internally, as a result of resistance from within the conductor

- UV exposure – insulations and sheaths can be significant impacted by ultraviolet light exposure causing them to crack and therefore present potential short circuit failures

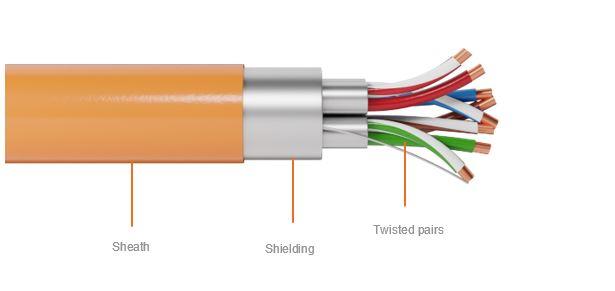

The different component layers within a data cable all play their part to reducing the chances of cable failure. With these potential failures in mind, cable manufacturers are continuously updating their products to satisfy their end user application needs. For example, supplying heavy-duty cabling to industrial sectors to prevent damage from electromagnetic interference, EMI, and hazardous materials, or developing single pair ethernet cables to offer lighter-weight and flexible characteristics to cater and enable confined space installations for equipment such as doors and motion equipment.

Cable manufacturers often carry out in-house testing to ensure the changes in design or processes do not impact quality levels, however, to obtain independent certification their products require testing and approval from an external certification body. BASEC is a third party approval and notification body, carrying out rigorous testing, inspection and certification assessment to enable approval processes which certify product quality in line with internationally recognised standards BS/ISO/IEC 11801, ANSI/TIA 568, and EN 50173.

Data cable testing and certification processes

Recognising this shift in the data industry, last year BASEC launched its testing and certification services by investing in a data communications cable testing laboratory collocated with the main cable facility in Milton Keynes, UK. As a key driver, the industrial demand for data has a combination of essential characteristics. The most important set of tests assess transmission performance, housing the laboratory on one site enables traditional cable performance properties to be tested under one roof, including electrical and mechanical, fire resistance and reaction as well as chemical resistance.

State of the art technology for reliable data transmission testing

Once a cable manufacturer has submitted the cable to enable certification assessments a full type test will be carried out to measure various transmission capabilities, some example tests include:

Insertion loss - electrical signals lose some of their energy as they travel along the cable, and this test is designed to measure the amount of energy that is lost along the way as the signal travels to its end destination. The testing experts, BASEC, use a high and low frequency test fixture featuring a high frequency network analysis, which takes thousands of measurements within one test to obtain an accurate insertion loss reading. Auto-switching software which connects the cable to the test system works to minimise external influences allowing the data to be recalled and segmented in one round of testing, providing an accurate set of test results, and minimising the number of samples needed throughout the certification cycle

Transfer impedance - cabling shields are designed to reduce transfer impedance and loss of data in transit. This test measures the current flow on a shield’s surface and highlights the effectiveness of the sheath material. An LCR meter provides a combination of accuracy and speed, multiple points frequency range as well as offering both high and low impedance range testing. Furthermore, an additional transfer impedance CoMeT 40 measures transfer impedance, screening and coupling attenuation of screened cables, connectors, or components

The CoMeT 40 measures impedance by placing the wire inside the pipe as shown above

More and more data cables or cabling networks are being used in industrial environments, thus the need for mechanical, ingress, chemical, electromagnetic - MICE testing - to measure environment compatibility and performance. The approval process at BASEC includes level 1 MICE compliance, assessing environmental challenges including shock and vibration. These tests are carried out in controlled environments and are used to simulate the extreme conditions that a cable product may face during handling and operation, such as mishandling, impact from items dropping and crushing the cable.

The future of data cable certification

End user expectations for data is only set to increase, with industrial organisations demanding higher data capacities, faster and over greater distances. This, coupled with the added adoption of smart devices in industrial settings, highlights the need for reliable, robust structured cabling infrastructures. End users utilising independently approved cables benefit from proven quality product evidenced by having undergone a rigorous auditing and testing process. Equally, BASEC’s worldwide presence offering localised regional customer support and the ability to deliver complete testing solutions under one roof provides the opportunity to access certification services via a one-stop shop, seamless process for manufacturers seeking data communications cable approvals.

Contact the team to discuss your data cable certification needs, or, to find out more information regarding the testing scope, download your free datacoms certification guide