Network development with single pair ethernet

Single-pair-ethernet (SPE) is an industrial solution to overcome challenges provided by traditional ethernet systems specifically aimed at industrial applications. Due to the reliability and flexibility that comes with the use of SPE there has been an increase in migration in the use of SPE in IoT devices. Highlighting the role of SPE in the digital transformation.

Introduction of single paired ethernet

As its name suggests, Single Pair Ethernet (SPE) cabling uses only one pair of wires to transmit data, as opposed to the two-pair that have long been standard in the majority of Ethernet cabling in use worldwide. The next big thing to happen within the data cabling market is the development and standardising of Single Pair Ethernet (SPE) cabling solutions.

SPE has opened up many opportunities within the data market allowing infrastructures to be more compact and lighter as well as reducing installation and material costs. The original motivation behind the IEEE standardising single-pair technologies was driven by the automotive industry. The wiring complexity within new vehicles was not only difficult to manage and control but was also seen as heavy and adding weight.

Like all aspects of daily life, the automotive manufacturers recognised that vehicles were being influenced by the Internet of Things (IoT) and needed to re-use data across multiple vehicle sub-systems. As they established that the traditional 4-pair cabling solution was not an option due to the added weight. The challenge for the IEEE and Ethernet cable manufacturers was to re-engineer and repackage the technology and make it ‘fit for purpose’. This original solution served the needs of the automotive industry well and SPE is now being routinely installed in vehicles globally. However, industrial automation, controls, and building automation industries have been slow to adopt SPE due to reach limitations.

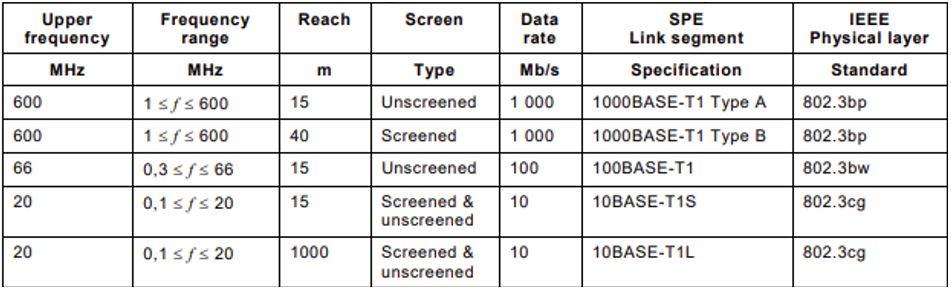

Figure 1: the bandwidth limitations that come with SPE is the main consideration when using SPE to manufacturer a device

The cabling standards

Section opener required, something like – ‘SPE standards of importance / key developments include:’

In the cabling industry, ISO/IEC is in the process of finalising amendments to accommodate the changes to ISO/IEC 11801, SPE.Part 1 - generic requirements, Part 3 - factory automation and process control, and Part 6 - distributed building services, which will include SPE permanent links and channels and is likely to be published over the next 2 years.

ISO/IEC 11801-1 AMD 1 recognises the use of both screened and unscreened cabling within the 3 new link and channel classes.

IEC 61156-11 Symmetrical single pair cables with transmission characteristics up to 600MHz – Horizontal Floor Wiring.

IEC 61156-12 Symmetrical single pair cables with transmission characteristics up to 600MHz – Work Area Wiring.

IEC 61156-13 Symmetrical single pair cables with transmission characteristics up to 20MHz – Horizontal Floor Wiring.

IEC 61156-14 Symmetrical single pair cables with transmission characteristics up to 20MHz – Work Area Floor Wiring.

The cables described within IEC 61156-11, -12, -13 and -14 are primarily intended to be used in screened channels. IEC 61156-13 and -14 do also make provisions for unscreened cables to be used, but only within 10BASE-T1 MICE E1 environments.

Delivering Power over SPE

Most networking industry participants are familiar with Power over Ethernet (PoE). PoE has been developed to run over either 2-pair or 4-pair cabling as determined within IEEE 802.3bt. However, to prepare PoE in SPE cabling for the industrial and building markets it has been recognised that it would be key to be able to deliver power over distances of up to 1000 metres.

With the publication of the 802.3cg standard, the IEEE introduced 6 additional classes of Power over Data Lines PoDL (Figure 3. refers). The new PoDL classes afford a broader scope for the deployment of SPE within the industrial and building automation market. ISO/IEC TS 29125: Edition 1.1 provides guidance regarding remote powering using SPE. Within the standards, consideration is given to temperature rise, bundling and other installation conditions providing the necessary recommendations and de-rating factors associated with SPE cabling delivering PoDL.

It also addresses the delivery of PoDL over bundled 1-pair cable channels including patch cords.

Figure 2. ISO/IEC TS 29125: Edition 1.1 2020

Installation planning and testing

IEC 61918:2018 for Industrial communication networks – Installation of communication networks in industrial premises is being amended to accommodate SPE. It is recommended that any potential planning, installation or testing of SPE networks is completed in accordance with Annex Q of IEC 61918 amendment 1. It is anticipated that the amendment to IEC 61918 will be published in 2021. If an SPE network is to be installed before the publication of IEC 61918 amendment 1 it is recommended that the guidance provided within ISO/IEC 11801 TR 9906.

In planning an SPE implementation due consideration should be given to the M.I.C.E environment requirements of the planned installation. IEC 61156-1 together with the additional guidance given within the appropriate substandard defined by IEC 61156-11 through IEC 61156-14 should be referenced.

Will SPE prevail at the ‘field level’

The jury is still out regarding the success of SPE within both the building and industrial automation markets.

What is now apparent, however, is that the technology is now defined and largely standardised with early devices now reaching the market. Several interest groups and associations, including the Ethernet Alliance, SPE Industrial Partners Network, SPE Systems Alliance, ODVA, TIA SPEC, are established globally to promote the technology. Contributors to these organisations include many of the global automation controls businesses.

At the industrial application protocol level e.g. Profibus, Profinet, Ethernet IP, CC-Link, etc, strong support is evident for SPE as a universal transport layer because this new technology will allow for the future development and integration of these established protocols within the digitalized world of automation.

Where does BASEC fit into this market?

Third-party testing and certification consider the critical applications of SPE, giving business owners’ architects and automation engineers reassurance and confidence behind “new to market” SPE cabling products.

At this early stage of SPE development and deployment, it is important, particularly in the absence of standard based field testers that components are assessed and independently certified using the reference channel models detailed within either ISO/IEC 11801-3.

Independent testing is critical to measuring cabling products for controls and instrumentation systems deployed within areas such as fire routes, access or entry points, security, and safety systems.

Bringing together its capabilities and knowledge in materials and transmission line testing the team at BASEC is ideally positioned to support the implementation of what many commentators believe to be the biggest growth market over the next 10 years.

For more information about the role of data cable for the end user download the BASEC data communication guide.