Cable products we can certify

We verify that the design, electrical, mechanical, material properties as well as any specialist performance meet the necessary requirements outlined in all the standards – in our UKAS accredited test lab.

One of the most common causes of confusion and issues on site when specifying cable is understanding the various standards cables must meet – and more importantly, how do you trust that the cable you have, is actually compliant and not going to damage your reputation as an installer or specifier? Most electric cable 'looks' the same – so how can you tell you have specified or are installing compliant cable?

A key part of our role is to ensure that the claims of conformity made by our clients (the cable manufacturers) about their cable are valid. The various cable standards refer to many supporting material standards and defined test methods. We verify that the design, electrical, mechanical, material properties as well as any specialist performance meet the necessary requirements outlined in all the standards – in our UKAS accredited test lab.

Here is a list of some of the common types of cable that BASEC approves and their relevant standards.

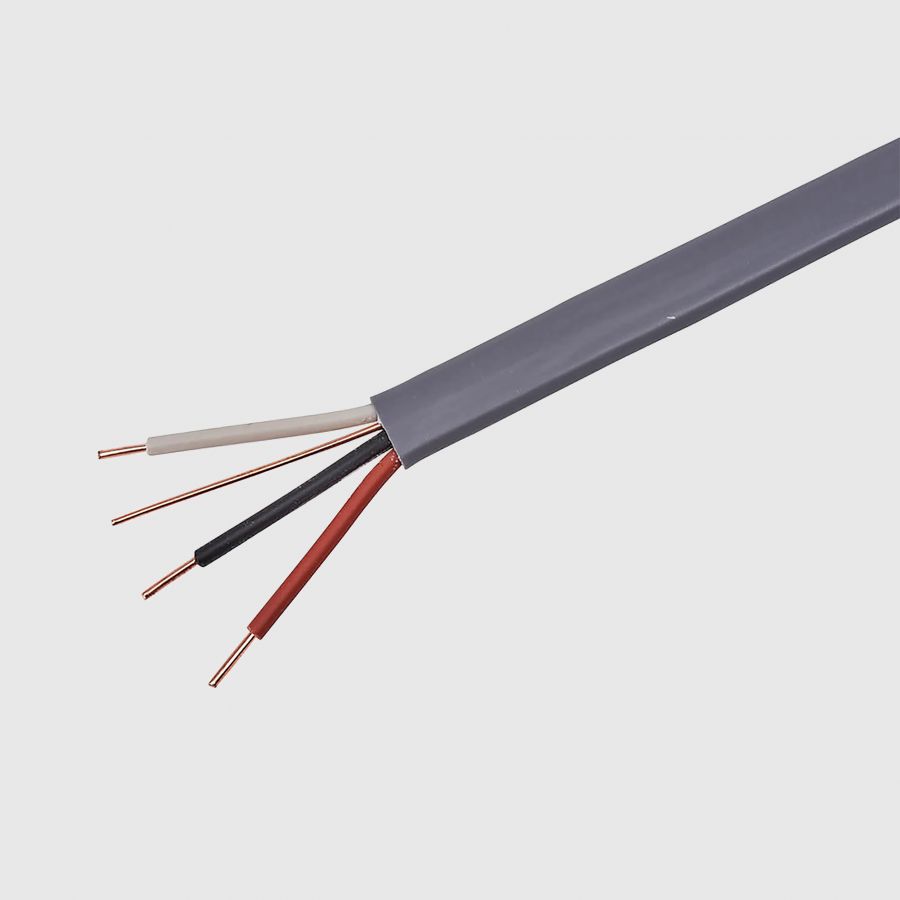

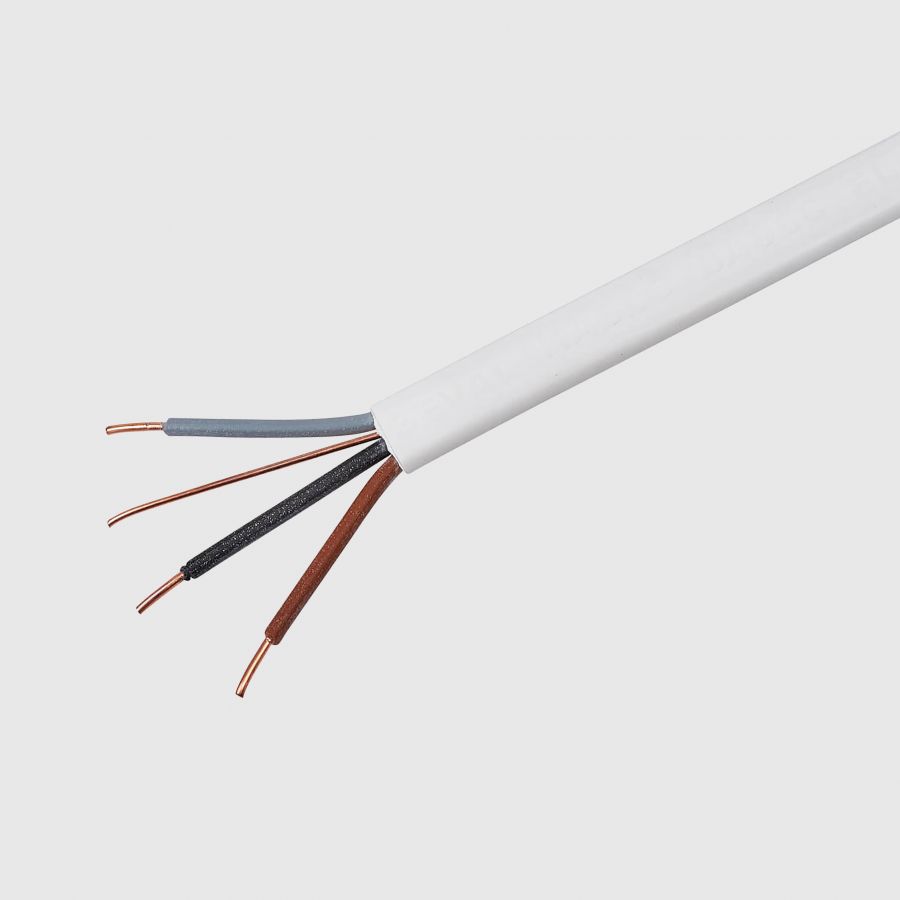

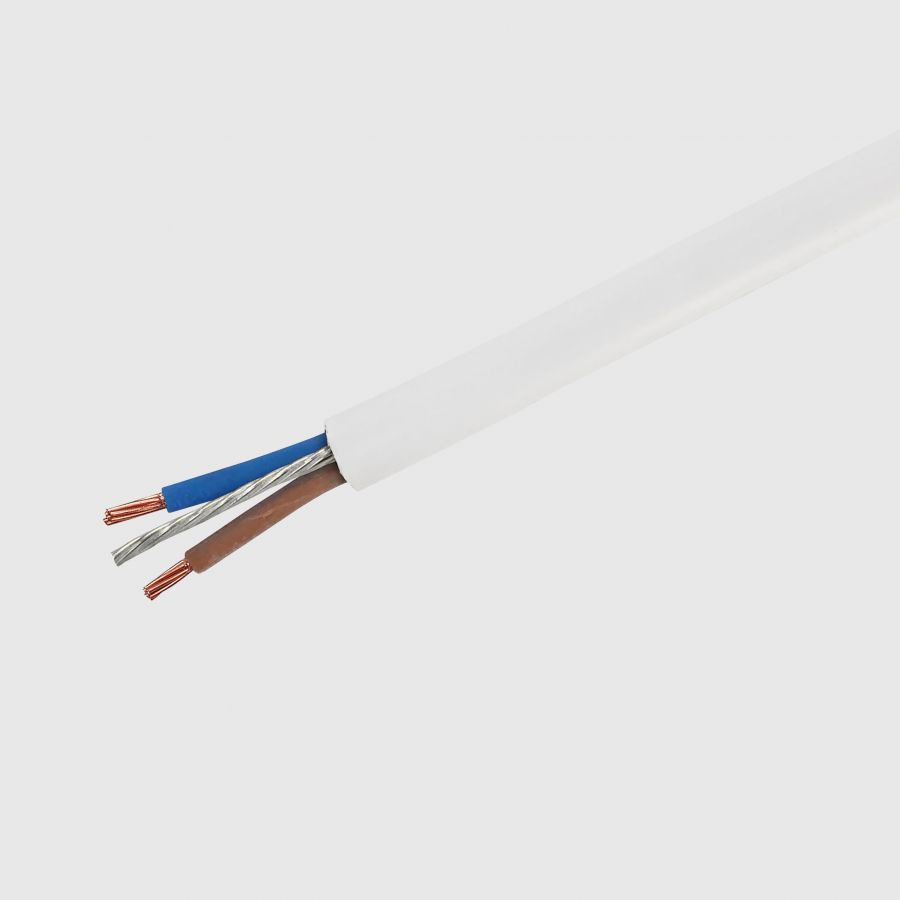

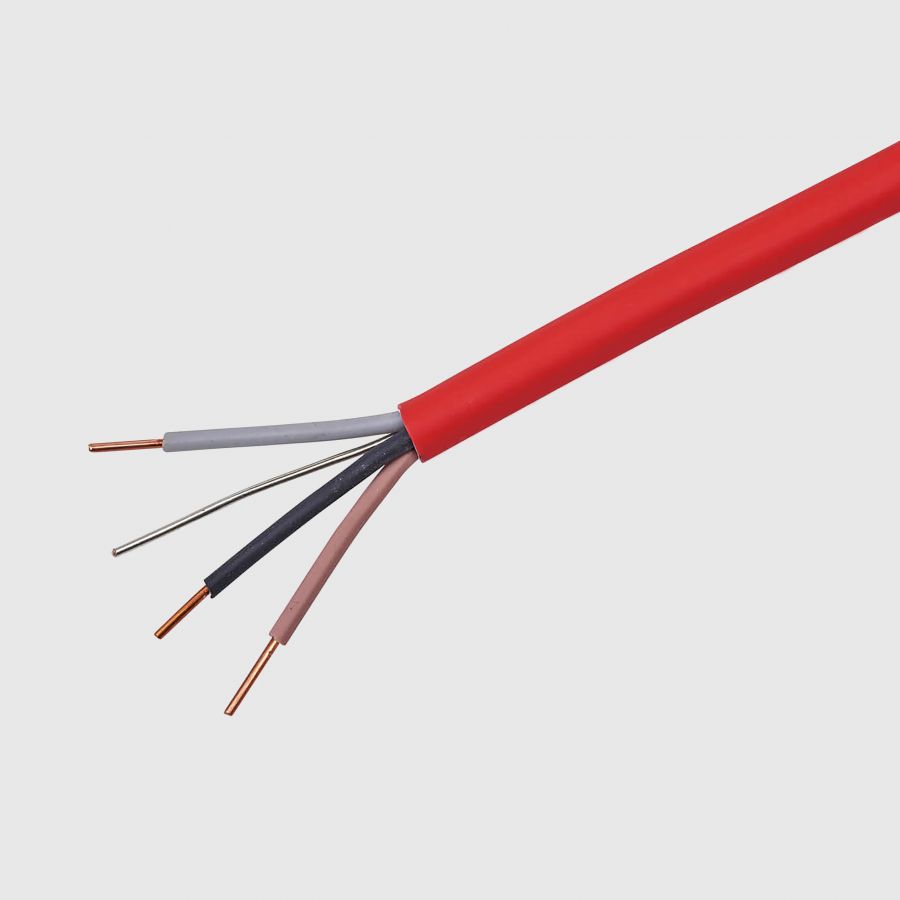

Installation Cables (building wire)

These cables are used in domestic and commercial premises for final circuit wiring.

BS 6004

Main standard for PVC wire and cable commonly used in final circuits in UK buildings, including the familiar "flat twin and earth" and "meter tails". Commonly known as PVC twin and earth, 6242Y, 6243Y.

BS 7211

Low smoke halogen free (LSHF) versions of many of the types of wire and cable found in BS 6004. Commonly known as low smoke twin and earth, 6242B, 6243B.

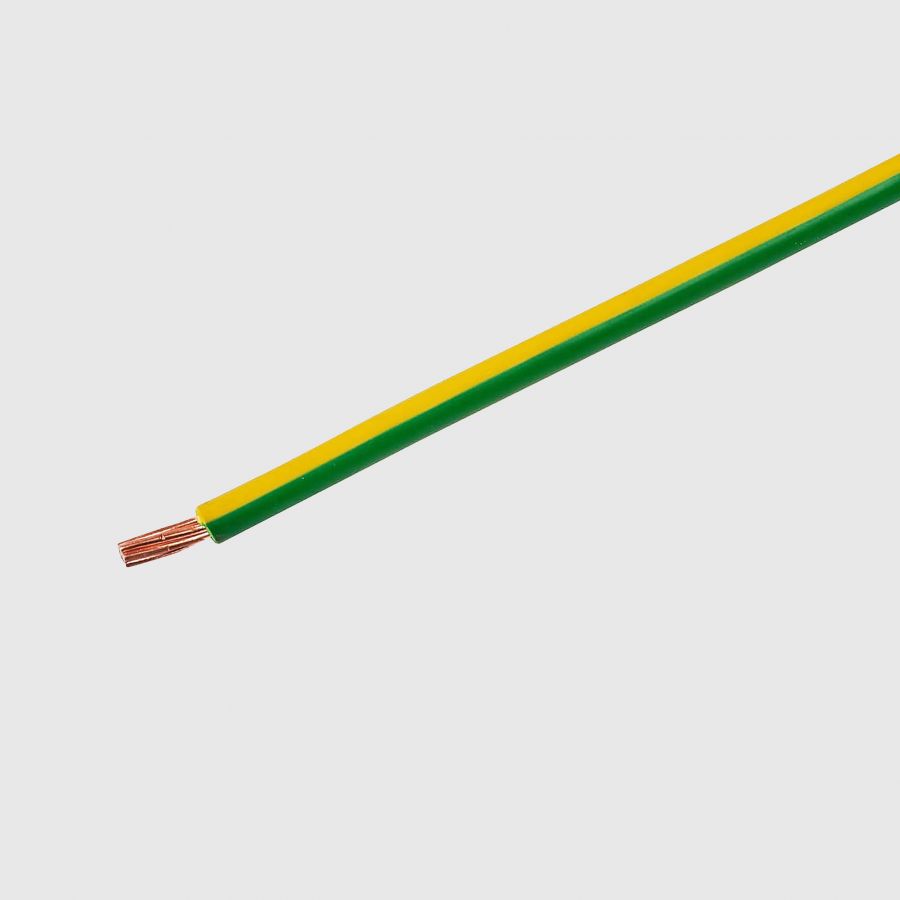

BS EN 50525 Series

Harmonised types of building wire, including “singles” and multicore cable with PVC or low smoke halogen free (LSHF) insulation/sheathing.

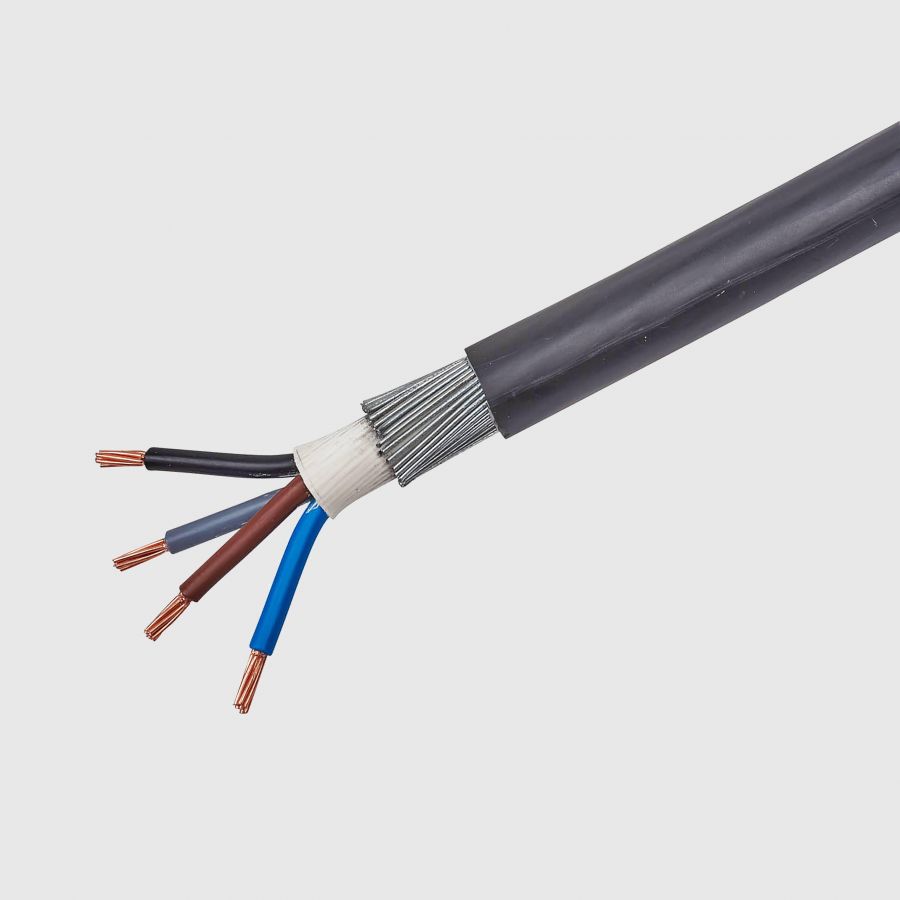

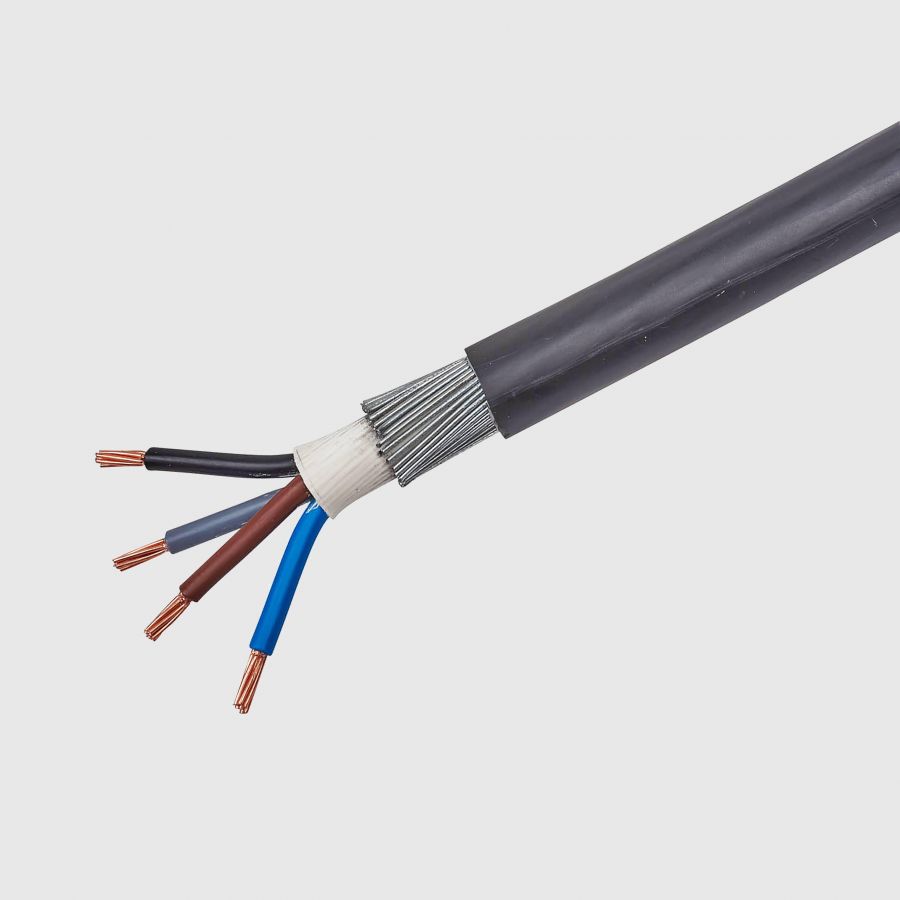

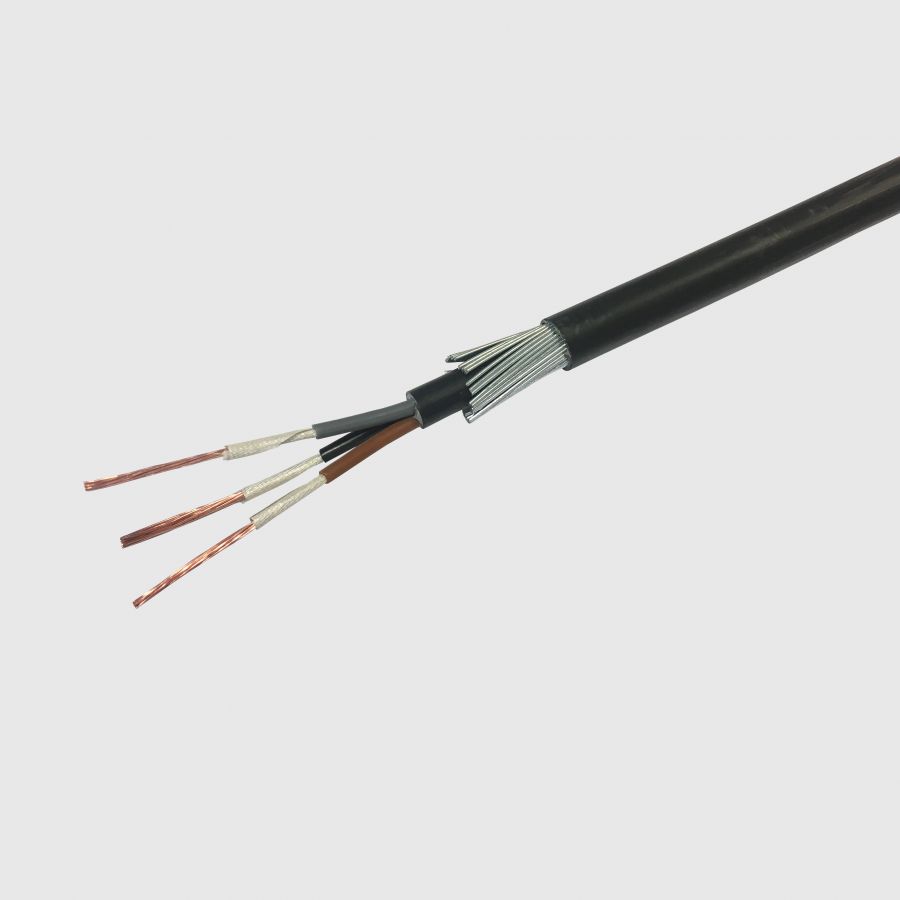

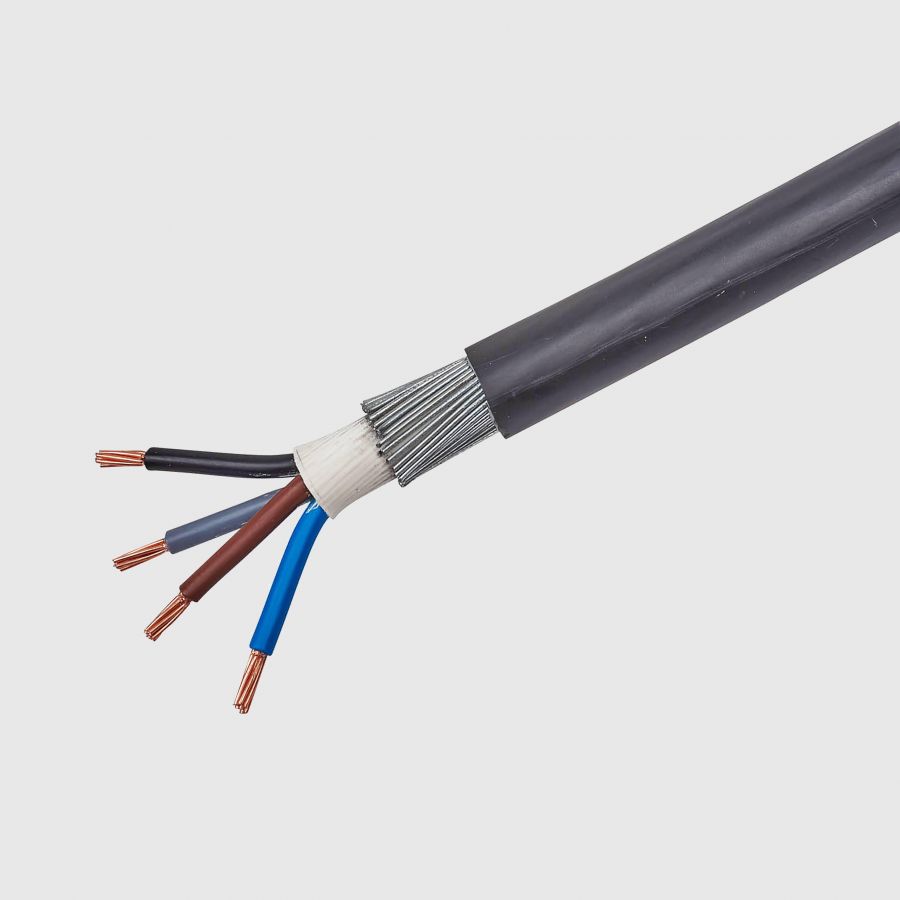

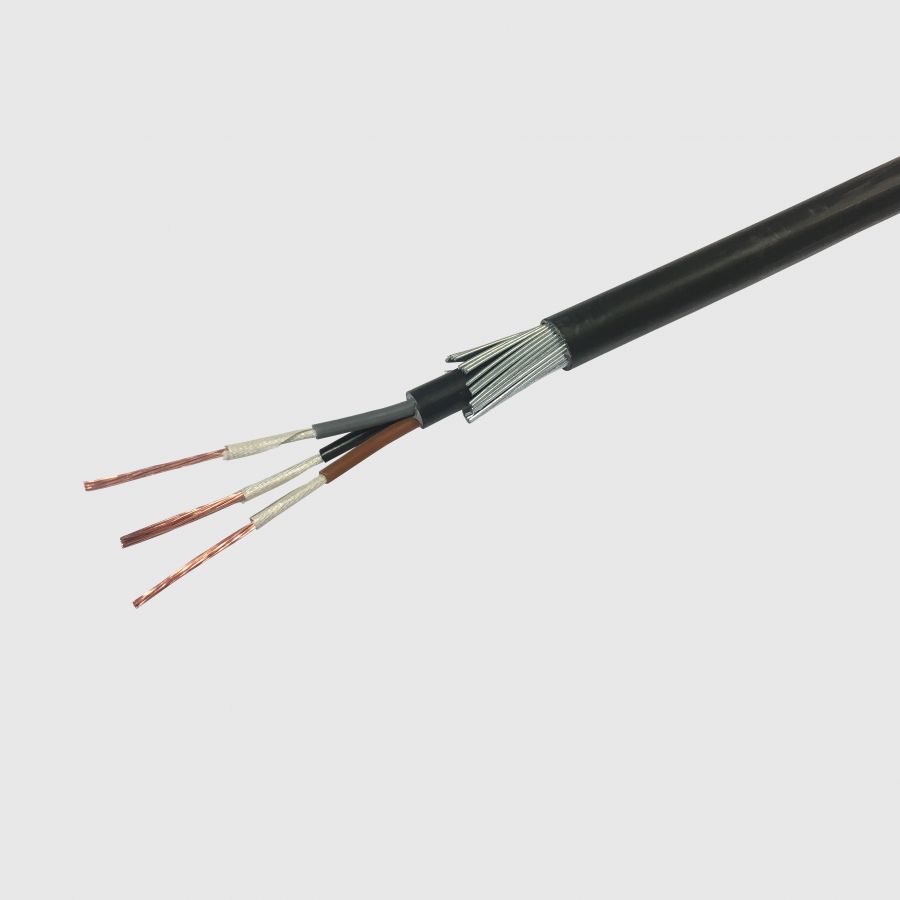

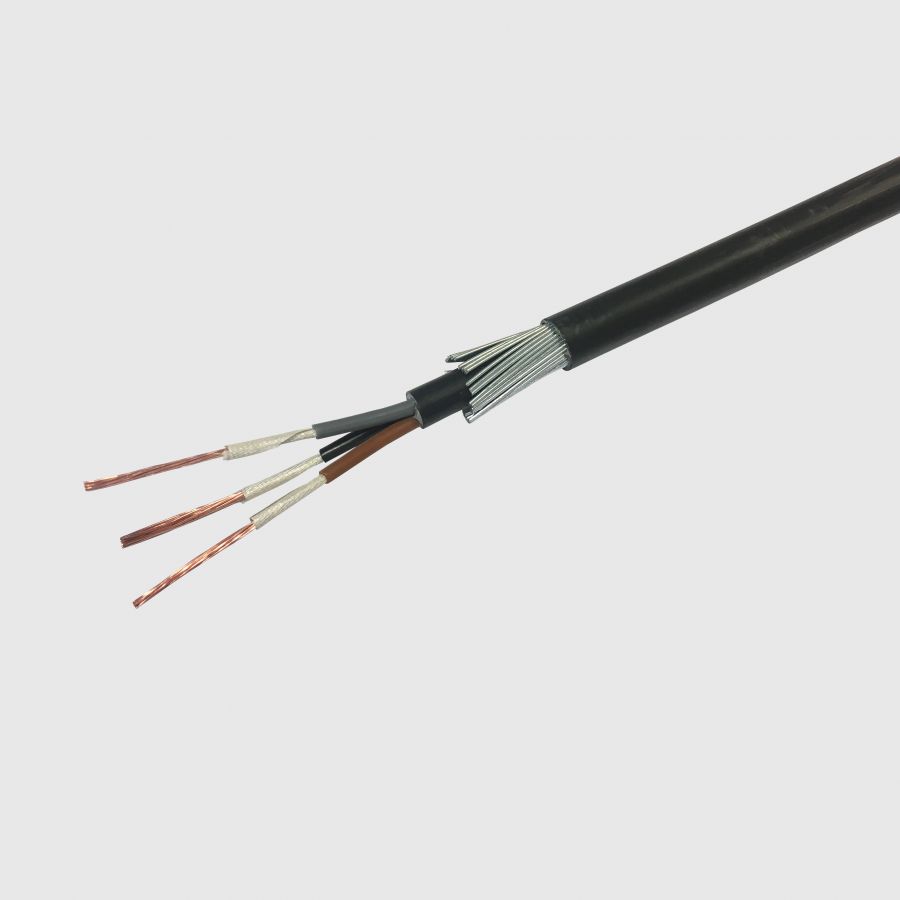

Power Distribution Cables (low voltage)

These cables are used for the supply and distribution of power to and within buildings.

BS 5467

Armoured power cables with PVC sheathing. Commonly known as PVC sheathed armoured, SWA, AWA.

BS 6724

Armoured power cables with low smoke halogen free (LSHF) sheathing. Commonly known as low smoke sheathed armoured, SWA, AWA.

BS 7846

Fire resisting armoured power cables with low smoke halogen free (LSHF) sheathing, and enhanced circuit integrity properties. Commonly known as fire resistant SWA, fire alarm / emergency lighting cable / soft skin fire alarm cable.

BS 7889

Non-armoured power cables with PVC sheathing. Commonly known as PVC sheathed unarmoured power.

BS 8436

Multi-core screened cables with low smoke halogen free (LSHF) sheathing for use in walls, partitions and building voids. Commonly known as nail proof.

BS 8573

Non-armoured power cables with low smoke halogen free (LSHF) sheathing. Commonly known as low smoke sheathed unarmoured power.

IEC 60502-1

Armoured and non-armoured low voltage power cables. Commonly known as IEC power / SWA.

Control and Instrumentation Cables

These cables are used internally in control panels and switchgear, and for industrial control and automation.

BS 6231

Single core instrument wire commonly known as "tri-rated". Commonly known as panel wire, trirated.

PAS 5308

Control and instrumentation cables. Commonly known as.

Flexible Cables

These cables have a wide variety of uses in construction and for powering appliances and equipment.

BS 6004 (Table 6)

Arctic grade flexible cable previously in BS 7919 now in BS 6004. Commonly known as arctic grade.

BS EN 50525 Series

Harmonised European standards for flexible cables. HAR scheme approval for these and other cables is also available.

Medium and High Voltage Cables

These cables are used by power supply utilities and in industrial applications for the supply of electricity to larger developments or for industrial applications.

BS 6622

Armoured medium voltage cables with PVC sheathing, for rated voltages up to 33 kV. Commonly known as PVC sheathed MV.

BS 7835

Armoured medium voltage cables with low smoke halogen free (LSHF) sheathing, for rated voltages up to 33 kV. Commonly known as low smoke sheathed MV.

BS 7870 (many parts)

Low voltage and medium voltage polymeric insulated cables for use by distribution and generation utilities. Commonly known as utility MV / LV.

IEC 60502-2

Armoured and non-armoured medium voltage power cables with a variety of types of construction and materials, for rated voltages from 6 kV up to 36 kV.

Data and Telecom Cables

BASEC offers approval to a range of data and telecom standards, including IEC 11801, BS EN 50173 and TIA/EIA 568.

Data Cable

Screened and unscreened cable. Including category 5 - category 8, horizontal and work area cable testing to comply with ISO/IEC 11801, ANSI/TIA 568 and EN 50173 standards

Fire Performance Cables

Most cable product standards include a basic requirement for single cable flame propagation testing. Some cables are made using polymer compounds that are low smoke halogen free (LSHF). Other cable types are specifically designed to have a high level of material performance during a fire and have fire survivability (circuit integrity) characteristics.

Many standards and codes of practice for safety-critical systems set requirements for fire performance cables, including BS 5839 for fire detection and alarm systems, BS 5266 for emergency lighting and BS 8519 for life safety and fire fighting applications. BASEC approves fire performance cables to various standards.

BS 5839-1

Alarm system design standard which sets two levels of performance – “Standard” and “Enhanced”. Commonly known as fire alarm cable.

BS 7629-1

British Standard type of “soft skin” fire resistant screened cables commonly used with fire alarms and emergency lighting. Commonly known as fire alarm / emergency lighting cable / soft skin fire alarm cable.

BS 7846

Fire resisting armoured power cables with low smoke halogen free (LSHF) sheathing, and enhanced circuit integrity properties. Commonly known as fire resistant SWA, fire alarm / emergency lighting cable / soft skin fire alarm cable.

BS EN 60702-1

(IEC 60702-1) Mineral insulated cables. Commonly known as fire alarm / emergency lighting cable / soft skin fire alarm cable.