Fire Rated Cables Explained: Design Standards and Critical Fire Tests

Fire Rated Cables are the cables which continue performing their intended function i.e. supply of power or control signals even in case of fire for some minimum time duration as per their fire rating. While at the same time, in case of fire, these cables should not emit halogen gases or generate high smoke which is harmful to health. Usually known as Fire Rated Cables, Fire Resistance Cables or Fire Survival Cables, however the actual cable type or construction will depend on the application, the fire duration rating, and the flame temperature, etc. Fire Rated cables can be used for power distribution, control signals, fire alarms, emergency lighting, and many more applications as per their criticality.

Depending on the cable construction, we can classify the fire rated cables into three cable types as below:

- Single core, Unarmoured, Unsheathed Fire Resistance Cables, 450/750V rated

- Fire Alarm / Emergency Lighting Cables, Unarmoured & Screened, 300/500V rated

- Fire Resistant Power & Control Cables, Armoured, 600/1000V rated

These cables have their individual cable design standards, their application and criticality. Their fire resistance test (circuit integrity test) standards, the flame temperature and fire rating duration also varies as per individual requirements. In some design standards, separate fire rating categories are also specified varying on fire performance.

Below are the cable design standards for above fire rated cable types and their fire categories:

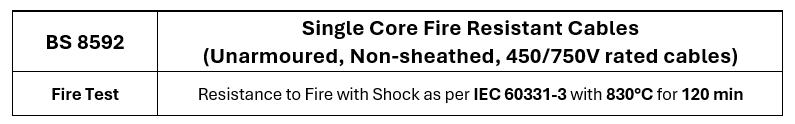

- BS 8592

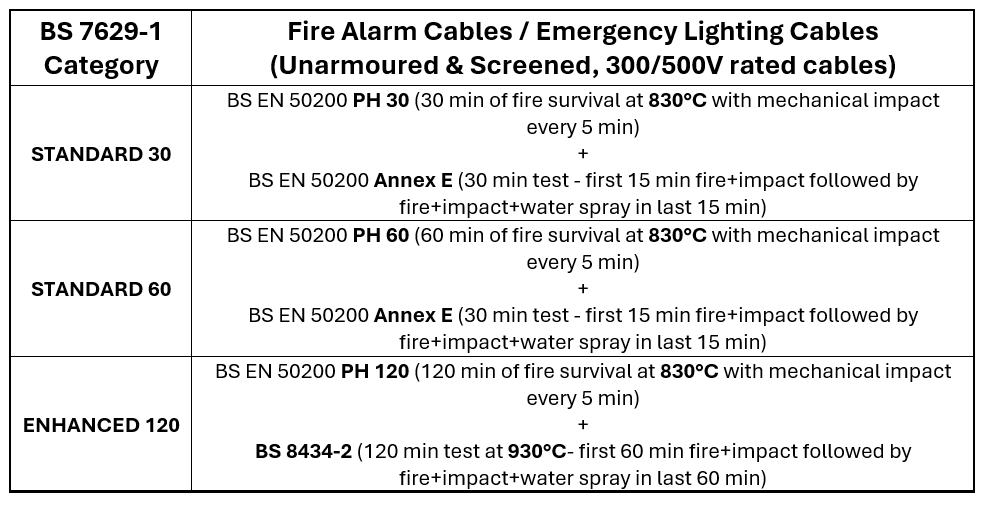

- BS 7629-1 (Fire Categories – Standard 30, Standard 60 and Enhanced 120)

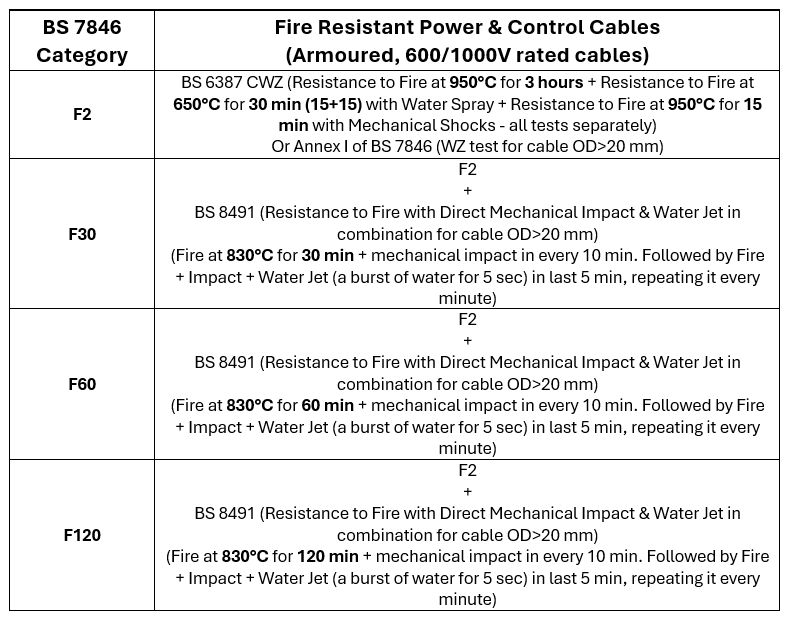

- BS 7846 (Fire Categories – F2, F30, F60 and F120)

Let’s understand these cable design standards, their fire categories and applicable fire tests with their flame temperature and duration in more detail:

BS 8592

Cable Construction:

Copper Stranded Class 2 Conductor, Fire Barrier Tape like Mica Glass Tape, Halogen-free Cross-linked Insulation Type EI5, 450/750V rated cable.

Cable Range:

Single Core – 1.5 to 70 sq.mm

Application:

Used in fixed installations (primarily in metal enclosure) in industrial areas, building and similar applications, where maintenance of power supply during a fire is required for a defined period.

Single Core Fire Rated cables product certified as per BS 8592 can be asked depending on application.

BS 7629-1

Cable Construction:

- Conductor: Plain or Tinner Copper Conductor with Class 1 or Class 2, CPC shall be Tinned Copper (full size & same class of main conductor), Drain wire for Auxiliary Cables shall be Tinned Copper of 0.5 sq.mm with Class 1 or Class 2

- Insulation: Fire Barrier Tape like Mica Glass Tape (optional), Cross-linked Elastomer EI2 or Halogen-free Cross-linked Insulation Type EI5

- Screen: Metallic or Laminated Metallic Screen(s) with metallic element in contact with CPR or drain wire.

- Sheath: Halogen-free Type LTS3, 300/500V rated cable.

Cable Range:

- 2-core*, 3-core, 4-core – 1.5 to 4 sq.mm with uninsulated full size CPC conductor

- Auxiliary Cables – 7-core, 12-core, 19-core* – 1.5 to 2.5 sq.mm with uninsulated 0.5 sq.mm drain wire

*2-core have additional 1.0 sq.mm size and 19-core have only 1.5 sq.mm size.

Application:

Primarily intended for use in emergency lighting, fire detection and fire alarm system circuits.

Product certified cables either STANDARD 30 or STANDARD 60 or ENHANCED 120 categories of BS 7629-1 can be asked depending on application.

BS 7846

Cable Construction:

- Conductor: Copper Stranded Class 2 Conductor

- Insulation: Fire Barrier Tape like Mica Glass Tape, XLPE Insulation Type GP8 or Cross-linked Elastomeric Insulation Type GP6 or Halogen-free Cross-linked Insulation Type EI5

- Bedding: Halogen-free compound

- Armour: Galvanised Steel Wire (SWA)

- Over Sheath: Halogen-free Type LTS1, 600/1000V rated cable.

Cable Range:

- 2-core, 3-core, 4-core – 1.5 to 400 sq.mm

- 5-core – 1.5 to 70 sq.mm

- Auxiliary Cables – 7-core, 12-core, 19-core, 27-core, 37-core – 1.5 to 4 sq.mm

Application:

Used in fixed installations in industrial areas, building and similar applications, where maintenance of power supply during a fire is required for a defined period.

Product certified cables either F2 or F30 or F60 or F120 category of BS 7846 can be asked depending on application.

To achieve the fire performance, other characteristic of cables like mechanical, material or electrical properties can be compromised affecting the overall performance of the cable. Therefore, overall compliance to fire rated cable design standard should be considered rather just asking for fire tests performances.

BASEC provides a complete solution of product certification for above fire rated cables which includes the material testing, mechanical & electrical tests, chemical, smoke, halogen, flame propagation tests and the fire tests (circuit integrity). The product certification involves factory audits, routine testing and market surveillance ensuring peace of mind for quality of BASEC marked fire rated cables.

To view listed and approved fire rated cable manufacturers, please use the website search feature.