Fire testing for cables - why is it important?

Fire testing ensures that cables maintain circuit integrity in critical conditions. From powering emergency lighting to supporting fire alarms, approved cables are designed to give people precious time to escape and protect vital systems during an emergency.

Learn answers to some of the most common fire testing questions with BASEC Lead Fire Technician Jed Stainthorp including key standards fire cables are tested to, any recent changes in testing methods and common issues resulting in test failures for fire resistance .

Could you provide an overview of your role and what it involves?

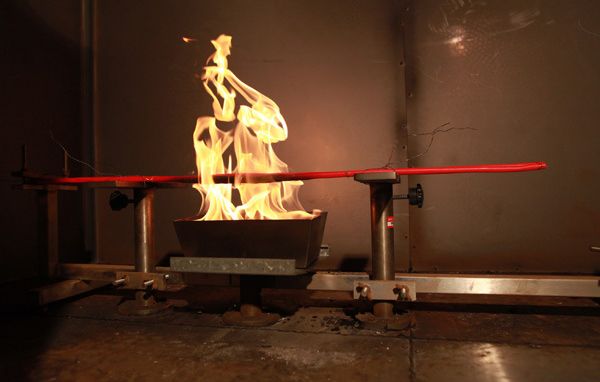

I oversee all the fire testing here at BASEC. This involves planning when testing will happen, making sure all of our equipment is in good condition and, performing fire tests.

What are some of the key standards you test fire cables to and why are they important?

BS EN 61034 – Smoke emission. This is important because smoke is the biggest hazard in a fire.

BS EN 50200 – Fire resistance. This test ensures that the fire alarm cables will continue to operate during a fire. This includes power and signals to smoke detectors, fire door closers, alarms and the fire control panel.

BS EN 50399 – Ladder test. This test is for all indoor cables and gives a rating on the additional heat and smoke that a cable will add to a fire. This allows designers to determine which locations are safe for each cable to be installed.

Are there any recent changes in the fire testing that is performed on cable products?

There is a new Ladder test standard (BS EN 50399:2022), this has several improvements to the test. These include more checks on the test data to ensure results are valid, larger pipes to the burner and, a new mounting method for certain types of smaller cables.

What common issues cause cables to fail fire resistance tests?

Some of the most common reasons for failure of a cable in relation to the fire resistance test include:

- Insulation quality: The quality and extrusion of the compounds used to make the insulation in fire resistant cables will affect how well it performs during testing.

- Water penetration: Most fire resistance failures happen when water is sprayed onto the cable, this is due to the water penetrating through all layers of the cable and touching a conductor.

- Insulation material: Certain cables contain XLPE (cross-linked polyethylene) insulation, this material has good electrical properties but will burn if exposed to fire. The protective tapes and sheathing need to be thick enough to protect the insulation from the flame.

To discuss fire testing requirements for your cable products please contact the team.