What makes up the cost of a cable? Are approved cables more expensive?

The cost of cable is an important aspect to be considered when planning commercial or industrial projects. Knowing the factors that impact the cost of cable is critical as it allows you to understand the structure behind the cost and choose the best option from the market.

Evaluating cost-efficiency is important in every industry, and the cable industry is not an exception. Cables are considered valuable assets and their impact on the total cost of a project is an essential factor to consider when planning your requirements, whether commercial or industrial.

Obtaining the best quality cable at the lowest cost is always a key priority. To better understand what makes the cost of a cable, it is essential to break it down into its parts, as well as the manufacturing processing, as follows:

- Raw materials

- Processing or manufacturing

- Scrap

- Packing

- Testing

- Overheads

Learn how each of these aspects impacts the final cost of your cable.

Raw Materials

The raw material costs are the total costs associated with the raw materials which are used to manufacture the finished product. This cost also includes the costs associated with shipping to manufacturer facilities, their handling, their customs clearance fees and any other cost linked to their door-to-door delivery.

Raw copper wire ready for processing |

Processing

The processing or manufacturing costs are associated with all manufacturing processes required to produce the cable, including all machines and their operators.

Cable manufacturing equipment |

Scrap

The scrap cost is the cost of material used during the manufacturing processes but not included on the final cable product. Examples of scrap cost are the material consumed during bleeding and the material employed for samples intended for the internal tests.

Packing

The packing costs include the cost of the cable drum, its lagging costs and if required reels or spools. These costs also include the packing process costs for coiling or cutting of the cables, if required to preserve the cable components during transportation, handling, and storage. Additional costs may also include shipment, which is often based on the contractual agreements between the cable manufacturer and its customer.

Testing

The cost of testing must also be considered. This is typically associated with the processes involved with internal testing, conducted on the entire cable and its individual materials as per the required national or international standards. It will include both routine and sample tests.

Overheads

The costs referred to as overheads comprise of all of the ongoing business expenses, which are not directly attributed to cable manufacturing. Some examples of overheads include employee wages, activities involved in marketing and sales, third party testing and product approval costs, utility bills, maintenance contracts, etc.

Are approved cables more expensive?

In examining all of the factors at play, understanding what significantly impacts the total cost of the cable is not as intuitive as it might seem. Being able to pin-point which costs, of those outlined above, have the biggest influence on final price is where you can build value into your decision-making process. Is it the raw material or processing costs? Is it the packing or testing costs? And, finally, is the myth that approved cables are more expensive valid?

|

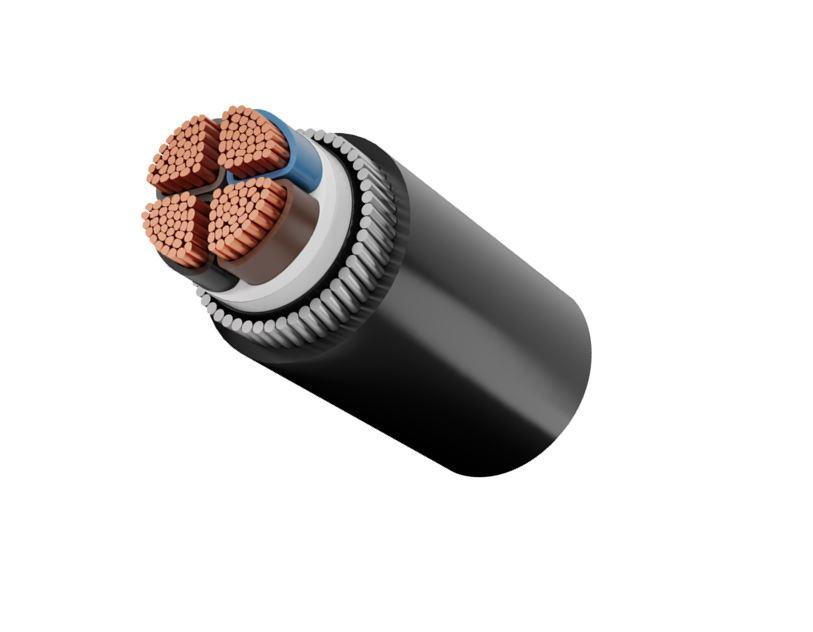

Let us take as an example the power cable 4X300 mm2, Copper Conductor, XLPE insulated, Steel Wire Armoured, and Halogen Free outer sheaths as per BS 6724.

Raw materials represent approximately 90% of the overall cable cost. Even more surprising is that conductor cost itself contribute to more than 80% of this. |

Cable cross-section to BS 6724 |

The other factors, such as workforce, processing, and overhead costs, are almost not significant. Overheads usually make up approximately 2% of the total cost of the cable. Third-party testing and approvals constitute a small fraction of it and therefore have a non-notable impact on the cost of cables.

BASEC Product Approval is no exception and does not impact the cost of the cable significantly. Nevertheless, independent product approvals have an enormous impact on quality and reducing the risk of failure in your end project applications.

|

Poor quality cable can cause complications, which have a knock-on effect to project delivery, making it challenging to meet deadlines, adding extra costs to remove, replace and undertake corrective work. BASEC Product Approval, once successfully achieved by a cable manufacturer, is displayed as a mark on the cable. It can only be gained after an in-depth assessment of the manufacturing management systems and continuous, rigorous cable testing. It gives serves the purpose of giving you, the end-user, peace of mind that the cable is safe, made to perform and fully compliant with your required design standard. |

BASEC approved marking printed on cable |

Choose quality - request BASEC Product Approval for your cables.