The role of cables in the event of a fire

A cables' fire performance can make the difference between a small accident and a dangerous fire outbreak. Learn more about the role of cables in fire conditions, the relevant safety standards and how they can be assessed.

| Firefighters in a fire outbreak |

In our daily life, we are constantly surrounded by cables, especially in buildings such as homes, workplaces, shopping malls and hospitals. Placing cables as a vital systems component whose quality and performance is directly related to our safety.

Throughout the world, in fact, approximately 51,000 electrical fires break out every year. Statistics state that failures in electrical distribution systems are the third leading cause of fire outbreaks.

Cables with lower safety standards can provoke the arcs that ignite the outbreaks, and can also be the reason as to why fires spread quickly, generate opaque smoke and toxic gases.

Low smoke emission cables

High-density opaque smoke can impact visibility and therefore hamper evacuation procedures.

Further to that, inhalation of toxic gases in found within smoke is the primary cause of fatalities, accounting for a staggering 44% of all fatalities - source: British Department for Communities and Local Government 2005.

For example, it is calculated that every year in Europe, gas and smoke emissions during fires claim 30,000 victims, as cited by CTIF 2003-2004. Controlling the opaque smoke generated, in a fire scenario, is a must as it facilitates the safe evacuation of building occupants. To ensure the safety of the end-users, cables should successfully pass smoke density tests as per IEC/EN 61034.

The smoke density test assesses the level of light transmitted, from one side of the chamber to the other, whilst the cable is under fire conditions. The light transmitted should not be below the standards specified level. The recommended performance requirement is compliance with the minimum value of light transmittance detailed in the standard. In IEC/EN 61034 this is 60%, some cable standards such as BS 6724 and BS 7846 require better performance and specify the minimum value for light transmittance as 70%. When specifying the required levels for your project, you should always specify the maximum level of protection, depending on the application.

| |

Flame retardant cables

Flame retardant cables are a vital element to limiting an outbreak, as they are designed to restrict the spread of a fire by reducing the rate of combustion.

There are many categories for flame retardant cables:

- IEC 60332-1

- IEC 60332-3-25 Cat. D

- IEC 60332-3-24 Cat. C

- IEC 60332-3-23 Cat. B

- IEC 60332-3-22 Cat. A

Flame retardance to IEC 60332-1 is the basic level of flame resistance. The level of resistance to flame propagation will increase to the highest level when compliant with IEC 60332-3-22 Cat. A.

Selection to the proper level of performance depends on the end application of your cables.

| |

Fire resistant cables

Fire resistant cables are designed to maintain circuit integrity and continue to work for a specific time under fire conditions. For these characteristics, they are used within the firefighting systems or in any function that should continue to operate during an outbreak, facilitating your emergency procedures.

Fire resistant cables are fit for purpose when the electrical load does not cut-off in the event of a fire.

To maintain cable functionalities in fire conditions it is vital to use special design and materials. Rigorous testing should also be carried out to ensure the compliance of your cables is in line with the standards criteria.

Many cables standards exist to guide the design and testing method for fire resistant cables, such as IEC 60502-1, BS 7846, BS 8592, and BS 7629.

Standards applicable to different categories of fire testing also exist and include IEC 60331, BS 6387, BS EN 50200, BS 8434-2, and BS 8491.

| |

Fire performance assessment

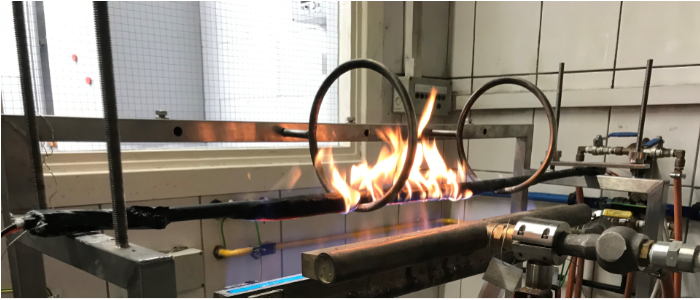

To assess your cables performance in a fire condition, there are different types of fire tests. Generally, they can be divided into:

- Fire only

- Fire and water spray

- Fire and mechanical load

- Fire, water spray and mechanical load

Each test can assess different cable categories required, where the duration of the test is varied for 30, 60, or 120 minutes for combined tests, and 180 minutes for fire only.

The different types of test are designed to simulate the different possible conditions that cables could be subject to in a fire situation. They may only experience fire scenarios, or there could be fire and water released from the firefighting system. In some cases, mechanical load may also be sustained due to the collapse of surrounding materials and infrastructures.

Currently, the regions with greatest attention to fire standards are Europe and the United Kingdom, which set an excellent example for the rest of the world via a clear fire classification framework. The European Construction Products Regulation (CPR) and now UK Conformity Assessed (UKCA) are mandatory regulations in the respective region. Both regulations use the same criteria to measure reaction to fire performance for all products used in the construction industry, encompassing all permanently installed cables.

CPR and UKCA regulations are, indeed, a step forward to better assessment of cable performance in fire conditions. The frameworks both classify cables into seven main classes: Aca, B1ca, B2ca, Cca, Dca, Eca to Fca, with additional classifications for smoke: S1a, S1b, S2, to S3, flaming droplets: d0, d1, to d2 and acidity: a1, a2, to a3. The classifications are determined by measuring the following parameters:

- Flame spread

- Heat release

- Smoke production

- Flaming droplets, and

- Acidity

Assessment procedures

In general, fire performance can be measured with different levels of assessment such as type tests and product approval.

Type testing can be helpful as it verifies the compliance of specific cable samples to particular standards at that moment in time.

Product approval, issued by a notified body and certification provide such as BASEC, is an in-depth surveillance scheme that through regular auditing, rigorous and continuous testing verifies that the cables and their manufacturing systems are consistently compliant to the quality and safety standards, including fire performance assessments.

Certification delivered independently through BASEC is one of the most rigorous programmes in the market and assures end users with the peace of mind that, in case of a fire, cable performance will function in line with its specifications.

Read about type testing and product approval here.

Conclusions

Cables are a vital component in powering and enabling our digital lives, and this makes their quality and safety directly related to the safety and quality we experience.

|

Low quality cables can not only trigger the arcs that ignite the fires, but also dramatically increase the rapidity and extension of fire spread, release dangerous smokes and toxic gases. To protect the occupiers of any building or infrastructure, it is vital that all cables are tested and certified for fire safety. BASEC certifies thousands of km of cables every year, ensuring that the quality, safety and fire performance meets the standards, which in turn helps you to evidence the use of compliant cabling products. To enquire about fire testing, certification or simply learn more, contact the team.

|

|

|