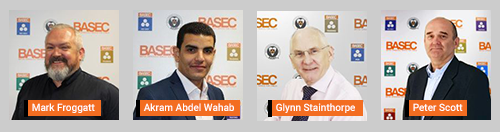

Meet the Technical Team

BASEC invests in local and knowledgeable technical team!

We took the opportunity to interview the team to learn more about their background, why they joined BASEC, and to learn about the challenges they see within the cable industry.

Why did you join BASEC?

Mark – Having worked with BASEC since 1997, I was excited about the opportunity to work for a growing brand with credibility and integrity to learn new skills and develop existing competencies. What appealed to me most, was the chance to work for a company that is focused on growth, to better the industry, and where I could be a key part of driving the strategy behind it.

Glynn – Before I joined the company, I had been a customer of BASEC for a long time. I really enjoy meeting customers within the industry, assisting with their requirements and learning from them. In BASEC I saw the opportunity to work with the cable industry from a different perspective, as well as a chance to work on a wide range of projects across many industry sectors.

Akram – My personal mission matches BASEC’s and I want to help verify and build confidence of manufacturers’ production processes, controls and management systems to ensure that they achieve quality outputs and meet all of the required and relevant regulations.

Peter – While I already had experience of working with product approvals, BASEC gave me the opportunity to work with a much wider range of businesses, and to help them implement management systems to achieve better performance.

Technical expertise

With almost 100 years of combined experience, the new technical team has time-served expertise of the cable industry. The team is experienced in all aspects of cable design, construction products regulation and fire compliance, polymer technology, new product and market development, electrotechnical competence and above all, application of testing recognised and relevant standards.

Between them, they have worked for a number of well-known and established companies, including: Draka, British Cables Company, British Cable Association, AEI, Huber & Suhner, CRU International, Elextrolux, Alfanar, Nexans and Elsewedy.

Sector knowledge

The team has also had exposure of working across an extensive number of industry sectors, including: utilities and construction, nuclear and renewable energies, power transmission, rail and transportation, oil and gas, fire security, aerospace and, integrated wiring systems.

Where do you see the value in BASEC?

Mark – BASEC offers the cable industry value in facilitating a level playing field. Everyone who undertakes certification through BASEC is treated exactly the same, I know this because I have been a customer, it is great for me as I know everything is being done to ensure consistency and compliance. Value is also gained through technical expertise through both my team of Technical Managers and our specialist Laboratory Technicians.

Glynn – Independent assessment of cable products is one of the main value-adds of working with BASEC. Manufacturers access unbiased and consistent testing from a reliable source, we are experienced and often the preferred partner for many across the worldwide cable industry. This independent stance helps us to use the knowledge we build on the industry to drive standardisation and ensure that the products manufactured are of the required quality.

Peter – In Asia, BASEC is a respected and recognised brand that is synonymous with quality, therefore manufacturers are interested in gaining and maintaining product approvals to give them a competitive edge. Contractors in the region also recognise BASEC as a mark of quality and often advise me that it enables their projects to stand head and shoulders above those who do not mandate BASEC cabling approvals.

What are the biggest challenges for the cable industry?

Mark – The manufacture of poor-quality cable products is one of the biggest challenges for the cable industry. Gaining accreditation to the mandatory standards is important to ensure that the cable products sold into the supply chain meet these industry recognised standards.

Glynn – The import of cable products into the UK and European markets has always presented a challenge for manufacturers, coming with a requirement to meet the applicable European standards. On the other hand, there is also an opportunity to drive demand of the use of independently approved cable products. As specifiers may look to source products from further afield, they will look for reassurances of quality. Our BASEC mark is printed on approved cable products and is a recognised brand name, that all of our customers always closely link to quality.

Akram – The biggest challenge in the cable industry is for manufacturers: finding the right balance between cable cost and quality. As the market is competitive, this can lead to manufacturers taking measures to reduce costs, which can compromise the quality of the cable products manufactured and supplied into projects. There is a knock-on effect to end users. Low cost cable products can be attractive, and therefore caution or technical understanding of the cable make-up and performance should be sought first, over attractive pricing.

Peter – The Asian market is oversaturated, with high levels of competition and well over 3,000 local manufacturers. In some places there are restrictions on who can supply product in each country. The cost of copper can also be a challenge, as there can be temptation to reduce costs by using alternative materials such as copper-plated metals instead of pure copper. This material is only used in specific applications, if it is mis-sold or misused a whole host of risks can arise.

Where can people meet you?

Mark – I am based in our Milton Keynes, UK head office, therefore customers can arrange to meet me here, at their factories and at the industry committee meetings I am involved with mark.froggatt@basec.org.uk

Glynn – I am based in the UK, at the BASEC head office. I also often meet with customers, attend industry exhibitions and present at conferences glynn.stainthorpe@basec.org.uk

Akram – As I am based in Dubai, I am positioned in the heart of the Middle East and Africa region. I am meeting with many companies right now including regulatory bodies, large consulting companies and of course, the cable manufacturers and supply chain akram.abdelwahab@basec.org.uk

Peter – I am based in the Philippines and I am often visiting customers as part of large audits and technical support meetings in the Asia region peter.scott@basec.org.uk