The global solar energy market, rapid growth, and a significant opportunity for cable manufacturers

The global market for photovoltaic (PV) solar energy systems is growing rapidly and, as all solar projects require extensive levels of cabling, represents a considerable opportunity for cable manufacturers. However, to successfully exploit this continuing development, it’s important to understand where growth is focused, why it is focused in these areas, as well as the challenges – both environmental and legislative – that it creates.

This article looks to highlight these issues and opportunities, giving cable manufacturers a clear insight into what it takes to meet the solar energy industry’s expectations. It also demonstrates how BASEC (British Approvals Service for Cables), through its cable testing and certification services, can help manufacturers achieve all necessary industry-related compliance requirements. This is set against a background of how the solar energy opportunities are distributed worldwide.

Why the solar energy industry is growing

The solar industry today owes the rapidity of its growth to multiple factors, rather than to one single reason. Fossil fuel pricing is expected to continue to rise over time, so future-proofing – by reducing dependence on such fuels – makes sound economic sense. Of equal importance, is the pressure that commercial organisations come under to meet their environmental obligations and build a sustainable, green energy policy. This pressure comes not only from shareholders, employees and trading partners, but also from government and related bodies in the form of mandatory legislation.

Accordingly, the major energy market players are leading the way with large-scale renewable energy projects; household names including Amazon, Apple, BBC, Ikea and Unilever have all invested in major schemes.

However, governments and individual consumers, as well as many other international businesses, have also contributed to the drive in demand for solar energy. This need for solar energy output has been met by a reported steady growth of installed solar energy systems.

Schemes based on renewable energy sources, including solar power, are also providing valuable solutions for remote and developing locations. Providing self-sufficient, renewable energy to rural communities in the developing world helps populations to work their way out of poverty with an ability to power their homes, schools, hospitals, stores and industries.

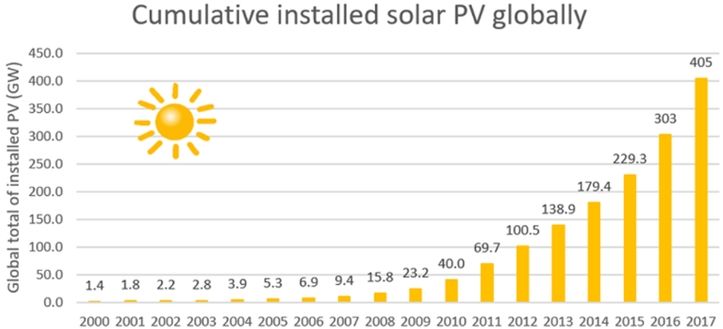

Overall, the latest figures indicate that the global installed capacity for solar photovoltaic (PV) systems exceeded 400 GW in 2017 (as shown in Fig.1).

Fig.1: Cumulative global growth of solar PV installations

These factors are contributing to plenty of business growth opportunities globally. In January 2018, GTM Research reported that 53 countries had set up tendering and auction programmes allowing the supply chain to bid for opportunities to support upcoming solar projects. The research also found that an additional 29 countries were planning to set up these programmes to recruit the best suppliers to fulfil their project specifications and requirements.

This statement is also reflected in figures released by the International Renewable Energy Agency (IRENA) relating to employment in the renewable energy sector. In 2017, this reached 10.3 million worldwide. The solar PV industry accounted for close to 3.4 million of those jobs, and was highlighted as the largest employer of all renewable energy technologies.

What role do cables play, and what are their critical requirements?

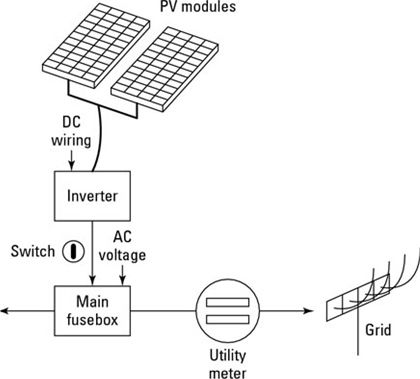

Fig.2 shows a simple domestic PV system, but the same principles equally apply to larger installations. Note in particular the use of DC cabling to interconnect the modules to one another, and to the inverter that converts their DC output to a usable AC supply. While the AC cables downstream of the inverter are usually within a building’s indoor, protected environment, the DC cables are typically outside, where they are exposed to environmental stresses and, potentially, human interference.

While the technical and legislative challenges associated with overcoming these issues are significant, the opportunities they represent to those cable manufacturers that can overcome them are correspondingly impressive.

Fig.2: Simple PV system block diagram

Following discussions with a number of firms involved in solar technology, BASEC recommends the following list of features that DC cables should be tested to maximise the potential opportunity:

- Abrasion resistance

- Flame retardance

- Halogen-free

- Humidity and water resistance

- Low smoke emission

- Ozone resistance

- Proofed against environmental salinity – especially for floating photovoltaics

- Proofed against chemical stresses – acids and alkalis

- UV resistance

- Withstanding large temperature ranges (-40°C to 90°C).

- Withstanding mechanical stress: compression, tension, bending and shear loads

Specifications for certain projects may also include external armouring for protection against rodent and insect damage, if relevant.

A declaration from cable manufacturers that their cabling has undergone rigorous testing isn’t sufficient - they must be able to prove to the industry that their solar products meet the pass requirements related to each of the specific tests involved in verifying the above product features. Using a testing and certification partner, such as BASEC, will provide the reassurance that operators and stakeholders require.

Using inappropriate cable shortens a project’s lifespan and many solar projects are being supported by local governments and, as such, can be accountable to public stakeholders for the return on financial investment.

The industry standard warranty-length provided by solar panel manufacturers is 25 years. As a result, this is sometimes also recommended as the lifespan for solar cables. However, a cable lifespan cannot be accurately given without reference to a temperature. The results from a thermal endurance test, as specified in IEC standards, can be used to predict life expectancy of cable products.

The location of solar projects necessitates longevity and low maintenance, particularly in the remote applications as mentioned above.

All cables must comply with relevant international legislation, as well as any project-specific demands. The two applicable standards for solar cables for use in DC apparatus are IEC 62930: ed 1.0:2017 and (BS) EN 50618:2014.

The standards are very similar in terms of their requirements, although the EN standard specifies the use of only low smoke, halogen-free types, whereas the IEC standard permits materials with or without these properties. There are also other differences such as the accommodation of class 2 cables and a slightly wider conductor size range in the IEC standard.

How can I produce cables that meet solar PV system requirements?

At a technical level, innovations in compounds and extrusion technology are now available to help cable manufacturers meet the solar industry’s unique specifications. Many cable manufacturers are working closely with project specifiers to manufacture cables that meet the design and local manufacturing standards’ requirements.

To reliably and efficiently meet international legislation, BASEC can assist with approval of cables to IEC 62930: ed 1.0:2017 and (BS) EN 50618:2014 standards. Class 5 conductor, low smoke, zero-halogen types are sufficiently similar, and thus can be assessed in a combined test programme to obtain certification for both product ranges via a condensed set of tests.

BASEC's teams of engineers, technicians and auditors possess extensive in-depth commercial, industrial and technical experience. As a result, BASEC has a reputation for professional and rigorous assessment processes, which ultimately lead to the issuing of our highly respected product certifications and test reports.

In addition, BASEC offers supporting services for cable makers, traders and users, including management system certification, bespoke type testing, impartial investigation of conformity issues, and testing and reporting in the event of disputes. Furthermore, Certificates of Assessed Design are available for innovative cable products, in the case where bespoke cable designs need independent testing.

BASEC is accredited by the United Kingdom Accreditation Service (UKAS) to provide certification to National, International and European cable product standards (e.g. BS, EN, IEC, ISO, and country specific), national and sector cable standards, and to management system standards for quality (ISO 9001), environmental management (ISO 14001), and health and safety (OHSAS 18001 / ISO 45001). BASEC also offers other certifications for cable stockist, rebranders, and sector-specific standards.

How is demand distributed globally?

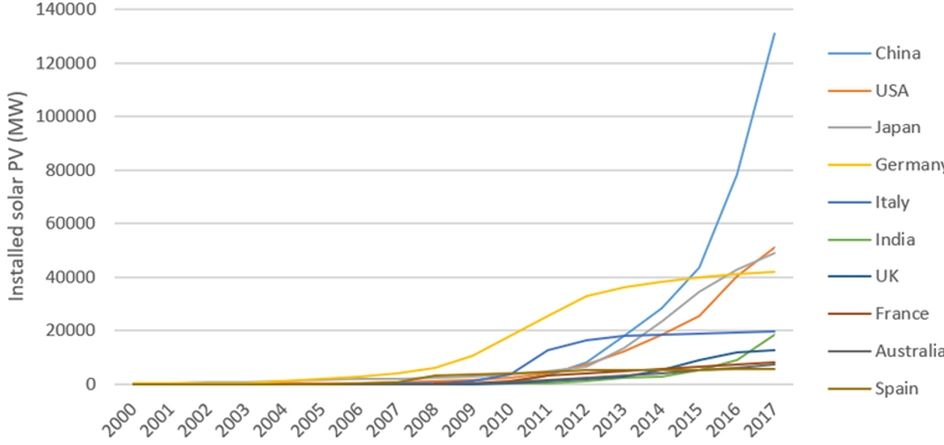

As early adopters of solar PV systems, Germany was recognised as a leader of solar installations for a decade up until 2015, after which it was overtaken by China (see Fig.3). China’s solar installation started to take off sharply in 2012, and in 2017 their newly installed base totalled significantly more solar capacity than the past top nine leading countries combined. Relative newcomers Japan and the USA have also overtaken Germany and have been tracking at a higher rate of installation. The data demonstrates that the race to produce renewable energy driven initiatives, is truly a global one. It is therefore essential that specifiers, buyers, cable distributors and manufacturers take note to use product that is compliant with the international and local standards, to ensure that the product supplied is commercially fit for purpose.

Fig.3: Cumulative installed solar PV - top 10 countries 2000 - 2017

Conclusion

This article has shown how multiple factors are contributing to the solar PV market’s rapid growth. Over time and as knowledge is rapidly developing, we are seeing a vast improvement in the quality and performance of the cables used in the solar industry. In years gone by these aspects have not fared as well as anticipated, therefore as the industry continually grows, we can also expect to see the technologies used to manufacture advance, to ensure reliable product enters the market. This growth is creating a healthy demand for external DC cabling, and a great opportunity for cable manufacturers that can overcome the challenges associated with meeting the market’s requirements. These manufacturers can obtain a competitive edge in this process by working with BASEC to gain independent product certification and approvals to demonstrate that the products supplied in to the market are compliant with all the necessary legislation.

The potential rewards for cable manufacturers who make this investment are considerable; as Walid Halty (Dvinci Energy, Forbes, May 2018) comments: “Today, Solar is the #1 most bankable sustainable technology, which has turned the industry into a gold rush.”

For further information on how BASEC can support your product certifications and approvals, please contact the team below:

Contact